Ladrillos refractarios con ganga de carbón y cenizas volantes en china

Introducción a los Peligros y Aprovechamiento Integral de Dos Residuos Sólidos, Ganga de carbón y cenizas volantes

2.1 Impact on the ecological environment

Coal gangue is piled up like a mountain, causando graves daños al medio ambiente, ecología, y la seguridad de la vida de las personas. Los componentes inorgánicos de la ganga de carbón son principalmente óxidos de silicio, aluminio, hierro, calcium, and magnesium, but there are also trace heavy metal elements such as P, Hg, Sn, Cu, Zn, As, cr, etc.. The stockpiling of a large amount of coal gangue not only occupies a large amount of scarce land resources, but also releases sulfides to pollute the environment, farmland, and groundwater. The accumulation of a large amount of storage over time and the increase in temperature due to internal heating will result in dense smoke in the coal gangue yard due to spontaneous combustion, releasing a large amount of harmful gases such as CO, CO ₂, SO ₂, H ₂ S, NO Å in the air, with SO ₂ being the main pollutant. The massive emission of harmful gases not only endangers the surrounding environment and air quality, affects the physical health of the mining area and nearby residents, but also affects the surrounding ecological environment, causing slow growth of trees, severe crop yield reduction, and in severe cases, tree and crop death. In addition to combustion, heavy metals are acid water generated by rain erosion, which flows into rivers or infiltrates into soil, causing groundwater and Soil contamination pollution. Another characteristic of coal gangue stored in the open air is its susceptibility to weathering and fragmentation. Some form fine particles of ash after spontaneous combustion, which undergo a series of complex reactions such as oxidation, decomposition, dehydrogenation, and condensation to form carbon black, Ceniza voladora, and particulate suspended solids, forming haze and directly affecting the local environment and people’s health.

Ceniza voladora, like coal gangue, is widely piled up in many places. Encountering strong winds and flying coal ash is a prominent environmental pollution problem that many places urgently need to solve. China has become a major coal producing country and the country with the highest coal consumption worldwide, as well as the country with the largest use of coal to produce waste fly ash. Due to the fact that fly ash generated by thermal power generation has become the biggest source of pollution for industrial solid waste, the placement of fly ash also requires the use of large areas of land, resulting in waste of land resources, and can have adverse effects on the surrounding air, water quality, and soil.

2.2 Overview of Comprehensive Utilization

Large amounts of land acquisition or the discharge of coal gangue and fly ash in mountain valleys will become history, and its way out is resource utilization. In the past 20 años, the government has issued many regulations, documents, and policies to promote the comprehensive utilization of coal gangue, providing strong support in finance and taxation, and continuously improving the comprehensive utilization rate of solid waste. In 2019, the comprehensive utilization rate of large comprehensive solid wastes will reach 55%, 5 percentage points higher than that in 2015, of which the comprehensive utilization rate of coal gangue and fly ash will reach 70% y 78% respectively [1]. Although satisfactory results have been achieved, there is still a significant gap compared to some developed countries. According to online materials from China Building Materials Industry Planning and Research Institute and Huajing Industry Research Institute, the utilization rate of coal gangue and fly ash in Japan is very high. Taking fly ash as an example, it reached as high as 98.3% en 2011, and the added value of utilization is also high, with cement being the dominant factor, accounting for 67.13%; Civil engineering accounts for 13.58%; Building panels, lightweight aggregates, and others account for 17.59%. In 2016, the utilization rate of fly ash in Europe was 83.4%, which not only had a high utilization rate but also diversified utilization channels. By 2016, fly ash in Europe had been basically utilized, con 40.8% being used as concrete admixtures; 17.0% replace cement in concrete; 16.4% for road materials; 5.5% for concrete blocks; 3.7% for others. In the early 1970s, Germany, France, and other countries achieved a comprehensive utilization rate of 30% para 50% of coal gangue. In the 1960s, Japan used coal gangue sintered lightweight aggregates for the construction field, reducing building weight by 20%, making its contribution to lightweight walls particularly important.

2.3 Application in the wall material industry

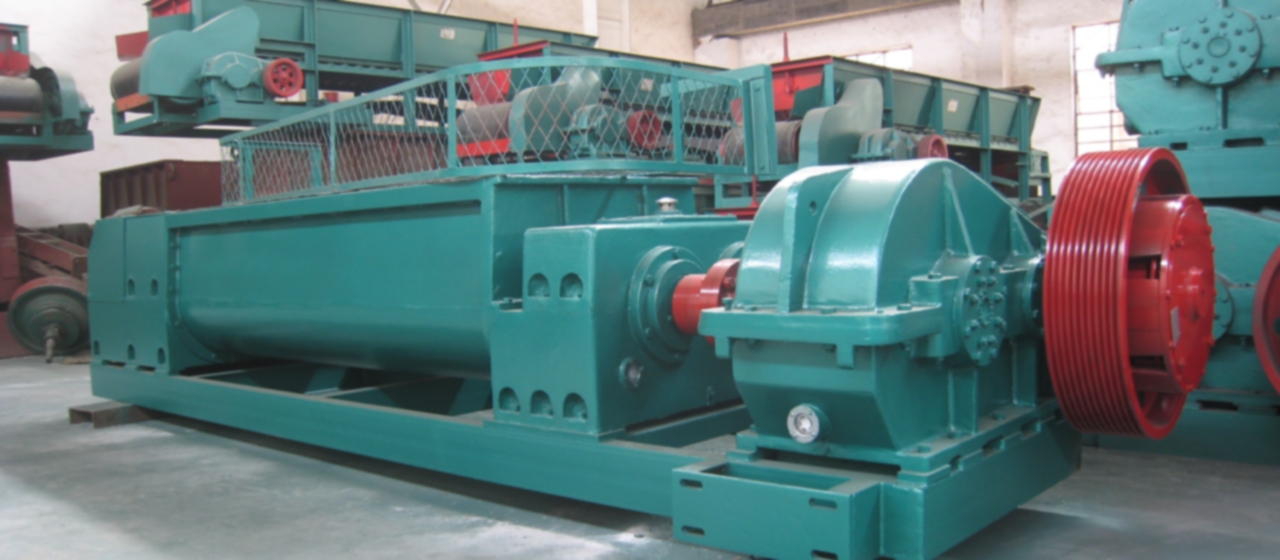

In developed countries, as early as the early 1960s, Germany, France, and Japan comprehensively utilized coal gangue and fly ash to produce various wall materials, which were widely used in construction projects. China introduced the technology of coal gangue and fly ash internal combustion bricks in the 1960s, with the aim of saving coal and reducing costs. In the 1970s, coal gangue and fly ash have become the main internal fuels, gradually developing into coal gangue and fly ash as the main internal combustion, supplemented by external coal. In the process of developing coal gangue and fly ash internal combustion bricks, the Ministry of Raw Materials holds various forms of study classes and achievement promotion and exchange activities on the production of various wall materials using coal gangue and fly ash. Before 1980, wall material brick and tile enterprises were mainly state-owned, and many state-owned brick factories created many technical experience and practical achievements in coal gangue and fly ash internal combustion bricks. Taking the utilization of coal gangue as an example, a production line with a design capacity of 15 million pieces of coal gangue bricks was built in the original Neijiang Machine made Brick and Tile Factory in 1973.

If we say that coal gangue and fly ash were only used as internal combustion materials around the 1960s, and the amount of utilization was very small, then it was only after the 1970s that a large number of coal gangue and fly ash were used as the main raw materials to produce wall products. The products were mainly solid bricks, but also porous bricks, Concrete masonry unit and hollow blocks. The earliest successful trial production of coal gangue bricks was carried out by Sichuan Yongrong Mining Bureau, and the Shigu Coal Mine in Gaoming City also built an annual production line of 15 million coal gangue bricks in the 1970s. In the 1980s, coal gangue and fly ash wall materials products developed rapidly. With the continuous improvement of coal gangue and fly ash sintered wall material products technology and the expansion of production scale, the equipment level seems to be unable to keep up with the development needs of coal gangue and fly ash brick products. In the late 1980s, China began a stage of introduction, innovation, and further development. Shanxi, Shandong, Ningxia, Anhui, Heilongjiang and other provinces have introduced equipment for producing wall materials using coal gangue and fly ash from the United States, Germany, Italy, and others. With the approval of the former State Economic and Trade Commission [2], a production line with an annual output of 60 million coal gangue Concrete masonry unit was introduced in Shuangyashan, Heilongjiang Province. Technically, it is required to make bricks from all coal gangue, and the assembled tunnel kiln is fired by ultra internal combustion. The product quality is Concrete masonry unit and porous load-bearing clean water wall bricks, and truly achieve “no soil for brick making, no coal for brick burning”. The product is of high grade. This introduction project has received strong support and high recognition from relevant central ministries and commissions, causing strong reactions within the industry. The coal gangue production line adopts a one-time sintering process and a super internal combustion coal gangue sintered brick process. Its equipment, Kaizhuang tunnel kiln and super internal combustion roasting technology have been fully digested and innovated, and its research and development achievements have won the second prize of the National Science and Technology Progress Award. It has been widely promoted and applied in China, making important contributions to the comprehensive utilization of coal gangue in the wall material industry in China. Provinces and cities with coal gangue have basically successfully built production lines, aumentando rápidamente la producción anual de ladrillos de material de pared de ganga de carbón en todo el país a más de 200 mil millones de ladrillos estándar. La producción anual de productos sinterizados en la industria de materiales para paredes de China es más que 810 mil millones de piezas [3], de los cuales los desechos sólidos a granel, como la ganga de carbón y las cenizas volantes, La protección del medio ambiente y otros productos nuevos de materiales de pared se han desarrollado rápidamente en los últimos años., con una producción anual de casi 600 mil millones de piezas, convertirse en la industria de utilización integral de residuos sólidos más grande de China. La utilización anual de residuos sólidos ha superado 135 millones de toneladas, y el ahorro anual de energía ha alcanzado 32 millones de toneladas de carbón estándar. El principal combustible utilizado para los productos de ladrillos y tejas sinterizados son los residuos sólidos a granel, como la ganga de carbón y las cenizas volantes.. Hay muy poco uso externo de energías fósiles como el carbón y el gas natural.. La energía residual, como la ganga de carbón y las cenizas volantes, representa más de 80%, mientras que el carbón y el gas natural sólo representan menos del 80%. Esto ha contribuido a la utilización integral de residuos sólidos y a la conservación de energía y reducción de carbono en toda la industria de materiales de construcción..