Briques réfractaires avec gangue de charbon et cendres volantes en Chine

Introduction aux dangers et à l'utilisation complète de deux déchets solides, Gangue de charbon et cendres volantes

2.1 Impact sur l'environnement écologique

La gangue de charbon s'entasse comme une montagne, causant de graves dommages à l'environnement, écologie, et la sécurité de la vie des personnes. Les composants inorganiques de la gangue de charbon sont principalement des oxydes de silicium, aluminium, le fer, calcium, et du magnésium, mais il y a aussi des traces d'éléments de métaux lourds tels que P, Hg, Sn, Cu, Zn, Comme, Cr, etc. Le stockage d'une grande quantité de gangue de charbon occupe non seulement une grande quantité de ressources terrestres rares, mais libère également des sulfures pour polluer l'environnement, les terres agricoles, et eaux souterraines. L'accumulation d'une grande quantité de stockage au fil du temps et l'augmentation de la température due au chauffage interne entraîneront une fumée dense dans la cour de la gangue de charbon en raison de la combustion spontanée, libérant une grande quantité de gaz nocifs tels que le CO, CO₂, SO ₂, H ₂ S, PAS d'Å dans l'air, avec SO ₂ étant le principal polluant. L'émission massive de gaz nocifs ne met pas seulement en danger l'environnement et la qualité de l'air., affecte la santé physique de la zone minière et des résidents à proximité, mais affecte également l'environnement écologique environnant, provoquant une croissance lente des arbres, forte réduction du rendement des cultures, et dans les cas graves, mort des arbres et des cultures. En plus de la combustion, les métaux lourds sont de l'eau acide générée par l'érosion pluviale, qui se jette dans les rivières ou s'infiltre dans le sol, provoquant une pollution des eaux souterraines et de la contamination des sols. Une autre caractéristique de la gangue de charbon stockée à l'air libre est sa sensibilité aux intempéries et à la fragmentation.. Certains forment de fines particules de cendres après combustion spontanée, qui subissent une série de réactions complexes telles que l'oxydation, décomposition, déshydrogénation, et condensation pour former du noir de carbone, cendres volantes, et particules solides en suspension, formant de la brume et affectant directement l’environnement local et la santé des personnes.

Cendres volantes, comme la gangue du charbon, est largement entassé dans de nombreux endroits. Les vents violents et les cendres de charbon volantes constituent un problème de pollution environnementale important que de nombreux endroits doivent résoudre de toute urgence.. La Chine est devenue un important pays producteur de charbon et le pays qui consomme le plus de charbon au monde., ainsi que le pays qui utilise le plus de charbon pour produire des déchets de cendres volantes. En raison du fait que les cendres volantes générées par la production d’énergie thermique sont devenues la plus grande source de pollution pour les déchets solides industriels., le placement des cendres volantes nécessite également l'utilisation de vastes superficies de terrain, entraînant un gaspillage des ressources foncières, et peut avoir des effets néfastes sur l'air ambiant, qualité de l'eau, et le sol.

2.2 Présentation de l'utilisation complète

L’acquisition massive de terres ou le rejet de gangue de charbon et de cendres volantes dans les vallées montagneuses appartiendront au passé., et la solution est l'utilisation des ressources. Dans le passé 20 années, le gouvernement a publié de nombreux règlements, documents, et politiques visant à promouvoir l’utilisation globale de la gangue de charbon, apporter un soutien solide en matière de finance et de fiscalité, et améliorer continuellement le taux d'utilisation global des déchets solides. Dans 2019, le taux d'utilisation globale des grands déchets solides complets atteindra 55%, 5 points de pourcentage supérieurs à ceux de 2015, dont le taux d'utilisation global de la gangue de charbon et des cendres volantes atteindra 70% et 78% respectivement [1]. Même si des résultats satisfaisants ont été obtenus, il existe encore un écart important par rapport à certains pays développés. Selon des documents en ligne de l'Institut chinois de planification et de recherche de l'industrie des matériaux de construction et de l'Institut de recherche industrielle de Huajing., le taux d'utilisation de la gangue de charbon et des cendres volantes au Japon est très élevé. Prenons l'exemple des cendres volantes, il a atteint jusqu'à 98.3% dans 2011, et la valeur ajoutée de l'utilisation est également élevée, le ciment étant le facteur dominant, comptabilité 67.13%; Les comptes du génie civil 13.58%; Panneaux de construction, granulats légers, et d'autres représentent 17.59%. Dans 2016, le taux d'utilisation des cendres volantes en Europe était 83.4%, qui avait non seulement un taux d'utilisation élevé mais également des canaux d'utilisation diversifiés. Par 2016, les cendres volantes en Europe étaient essentiellement utilisées, avec 40.8% utilisé comme adjuvant pour le béton; 17.0% remplacer le ciment dans le béton; 16.4% pour matériaux routiers; 5.5% pour blocs de béton; 3.7% pour les autres. Au début des années 1970, Allemagne, France, et d'autres pays ont atteint un taux d'utilisation global de 30% pour 50% de gangue de charbon. Dans les années 1960, Le Japon a utilisé des agrégats légers frittés par gangue de charbon pour le domaine de la construction, réduisant le poids du bâtiment en 20%, rendant sa contribution aux murs légers particulièrement importante.

2.3 Application dans l'industrie des matériaux muraux

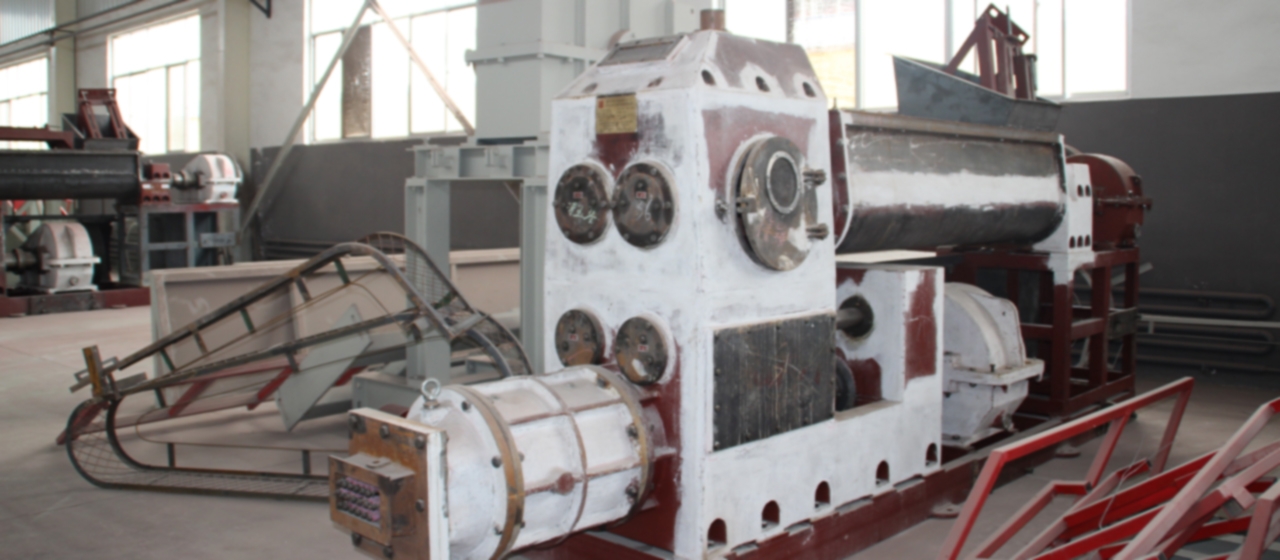

Dans les pays développés, dès le début des années 1960, Allemagne, France, et le Japon a largement utilisé la gangue de charbon et les cendres volantes pour produire divers matériaux de mur, qui ont été largement utilisés dans les projets de construction. La Chine a introduit la technologie de la gangue de charbon et des briques à combustion interne de cendres volantes dans les années 1960, dans le but d'économiser du charbon et de réduire les coûts. Dans les années 1970, la gangue de charbon et les cendres volantes sont devenues les principaux combustibles internes, se transformant progressivement en gangue de charbon et en cendres volantes comme principale source de combustion interne, complété par du charbon externe. En cours de développement de briques à combustion interne de gangue de charbon et de cendres volantes, le ministère des matières premières organise diverses formes de classes d'études et d'activités de promotion et d'échange de réalisations sur la production de divers matériaux de mur à l'aide de gangue de charbon et de cendres volantes. Avant 1980, les entreprises de briques et de tuiles de matériaux de mur appartenaient principalement à l'État, et de nombreuses usines de briques appartenant à l'État ont créé de nombreuses expériences techniques et réalisations pratiques dans le domaine des briques de combustion interne à base de gangue de charbon et de cendres volantes.. Prenons l'exemple de l'utilisation de la gangue de charbon, une ligne de production d'une capacité nominale de 15 millions de morceaux de briques de gangue de charbon ont été construits dans l'usine originale de briques et de tuiles fabriquées à la machine à Neijiang en 1973.

Si l’on dit que la gangue de charbon et les cendres volantes n’étaient utilisées comme matériaux de combustion interne que vers les années 1960, et la quantité d'utilisation était très faible, ce n'est qu'après les années 1970 qu'une grande quantité de gangue de charbon et de cendres volantes ont été utilisées comme principales matières premières pour fabriquer des produits muraux.. Les produits étaient principalement des briques pleines, mais aussi des briques poreuses, Elément de maçonnerie en béton et blocs creux. Le premier essai réussi de production de briques de gangue de charbon a été réalisé par le Bureau minier de Yongrong du Sichuan., et la mine de charbon Shigu dans la ville de Gaoming ont également construit une ligne de production annuelle de 15 millions de briques de gangue de charbon dans les années 1970. Dans les années 1980, les produits de matériaux de gangue de charbon et de cendres volantes se sont développés rapidement. Avec l'amélioration continue de la gangue de charbon et de la technologie des matériaux de paroi frittés de cendres volantes et l'expansion de l'échelle de production, le niveau d'équipement semble ne pas pouvoir suivre les besoins de développement des produits en gangue de charbon et en briques de cendres volantes. A la fin des années 1980, La Chine a entamé une phase d'introduction, innovation, et développement ultérieur. Shanxi, Shandong, Ningxia, Anhui, Le Heilongjiang et d'autres provinces ont introduit des équipements pour produire des matériaux muraux à partir de gangue de charbon et de cendres volantes en provenance des États-Unis., Allemagne, Italie, et d'autres. Avec l'approbation de l'ancienne Commission nationale de l'économie et du commerce [2], une ligne de production avec une production annuelle de 60 million de gangue de charbon Une unité de maçonnerie en béton a été introduite à Shuangyashan, Province du Heilongjiang. Techniquement, il est nécessaire de fabriquer des briques à partir de toute la gangue de charbon, et le four tunnel assemblé est chauffé par ultra combustion interne. La qualité du produit est une unité de maçonnerie en béton et des briques murales poreuses et porteuses d'eau propre., et vraiment réaliser “pas de terre pour fabriquer des briques, pas de charbon pour brûler les briques”. Le produit est de haute qualité. Ce projet d'introduction a reçu un fort soutien et une grande reconnaissance de la part des ministères et commissions centraux concernés., provoquant de vives réactions au sein de l’industrie. La ligne de production de gangue de charbon adopte un processus de frittage unique et un processus de brique frittée de gangue de charbon à combustion interne.. Son équipement, Le four tunnel Kaizhuang et la technologie de torréfaction à combustion interne superbe ont été entièrement digérés et innovés, et ses réalisations en matière de recherche et de développement ont remporté le deuxième prix du National Science and Technology Progress Award. Il a été largement promu et appliqué en Chine, apporter d'importantes contributions à l'utilisation globale de la gangue de charbon dans l'industrie des matériaux muraux en Chine. Les provinces et les villes touchées par la gangue du charbon ont pratiquement réussi à construire des lignes de production, augmentant rapidement la production annuelle de briques de matériaux de mur de gangue de charbon dans tout le pays à plus de 200 milliards de briques standards. La production annuelle de produits frittés dans l’industrie chinoise des matériaux muraux est supérieure à 810 milliards de pièces [3], dont les déchets solides en vrac tels que la gangue de charbon et les cendres volantes, la protection de l'environnement et d'autres nouveaux produits de matériaux muraux se sont développés rapidement ces dernières années, avec une production annuelle de près de 600 milliards de pièces, devenir la plus grande industrie d'utilisation complète des déchets solides en Chine. L'utilisation annuelle des déchets solides a dépassé 135 millions de tonnes, et l'économie d'énergie annuelle a atteint 32 millions de tonnes de charbon standard. Le principal combustible utilisé pour les produits de briques et de tuiles frittées est constitué de déchets solides en vrac tels que la gangue de charbon et les cendres volantes.. Il y a très peu d’utilisation externe d’énergies fossiles telles que le charbon et le gaz naturel. Les déchets énergétiques tels que la gangue de charbon et les cendres volantes représentent plus de 80%, alors que le charbon et le gaz naturel ne représentent que moins de 80%. Cela a contribué à l'utilisation globale des déchets solides, aux économies d'énergie et à la réduction des émissions de carbone dans l'ensemble de l'industrie des matériaux de construction..