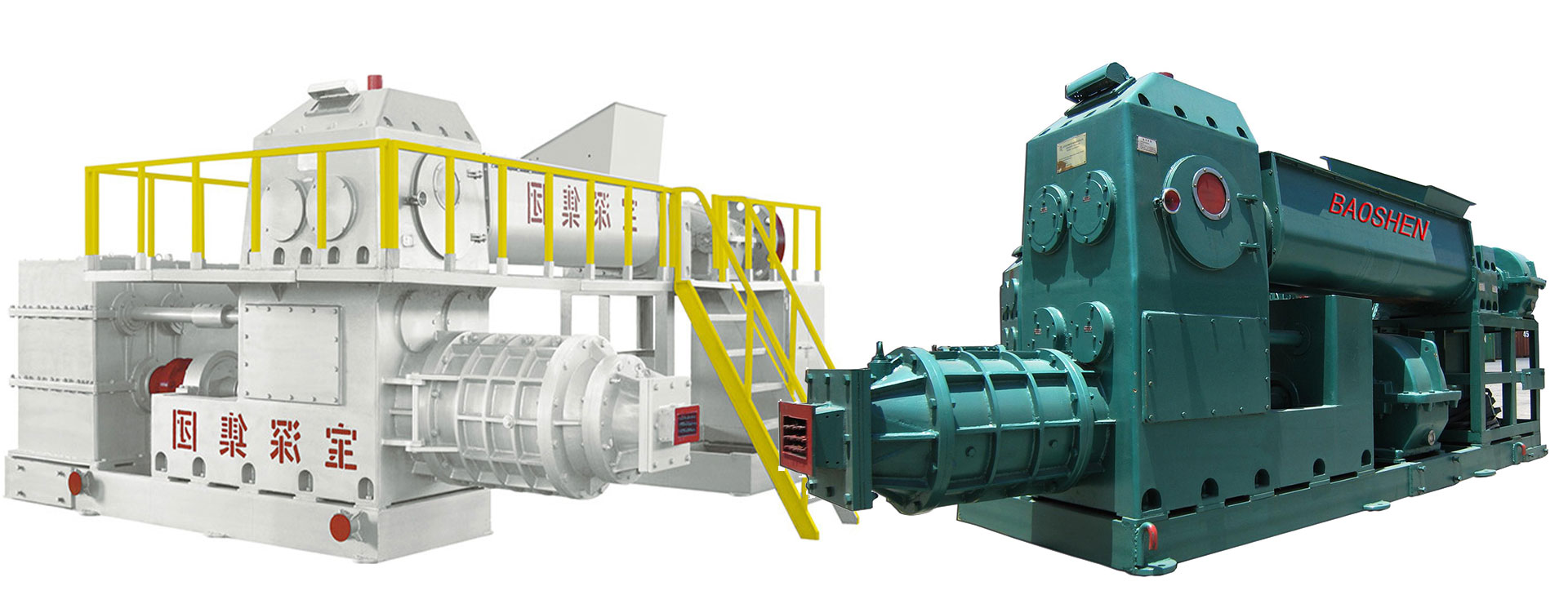

Cina estrusore superiore come Manutenzione e servizio

Prossimo, I macchinari per estrusori Baoshen ti spiegheranno che gli operatori devono avere familiarità con le caratteristiche strutturali dell'estrusore che utilizzano, in particolare le caratteristiche strutturali della vite, le caratteristiche degli strumenti di controllo per il riscaldamento e il raffrescamento, le caratteristiche della testa della macchina e le condizioni di montaggio, so as to correctly grasp the extrusion process conditions and operate the machine correctly.

The operation methods of extruding different plastic products are different, but they also have their own similarities. The following is a brief introduction to the same operation steps and precautions when extruding various products.

1. Preparation before start-up

(1) Plastic used for extrusion molding. Raw materials shall meet the required drying requirements, and further drying is required if necessary. The raw materials shall be sieved to remove agglomerates and mechanical impurities.

(2) Check whether the water, electricity and gas systems of the equipment are normal, ensure that the water and gas circuits are unblocked without leakage, whether the electrical system is normal, and whether the heating system, temperature control and various instruments work reliably; Conduct low-speed test run of the auxiliary machine with no load, and observe whether the equipment operates normally; Start the vacuum pump of the sizing table and observe whether it works normally; Lubricate the lubricating parts of various equipment. If any fault is found, it shall be eliminated in time.

(3) Installation head and setting sleeve. Select the machine head specification according to the product variety and size. Install the machine head in the following order.

① The heads shall be assembled together and integrally mounted on the extruder.

② Before assembling the machine head, wipe off the grease applied during storage, carefully check whether there are bumps, scratches and rust spots on the surface of the cavity, polish it if necessary, and then apply a layer of silicone oil on the surface of the runner.

③ Assemble each plate of the machine head in sequence, apply high-temperature grease on the bolt thread, and then screw on the bolt and flange.

④ Place the perforated plate between the machine head flanges to ensure that the perforated plate is pressed without overflow.

⑤ Before tightening the fastening bolts of the connecting flange between the die and the extruder, the horizontal position of the die shall be adjusted. The square die can be leveled by the horizontal method, and the round die shall be leveled by the bottom of the die based on the rubber bottom of the shaped model.

⑥ Tighten the connecting flange bolts, tighten the head fastening bolts, install the heating ring and thermocouple, and note that the heating ring should be close to the outer surface of the head.

⑦ Install the setting sleeve and adjust it in place. Check whether the main machine, the setting sleeve and the center line of the tractor are aligned. Tighten the fixing bolts after adjustment. Collegare ogni tubo dell'acqua e tubo del vuoto del manicotto di dimensionamento.

⑧ Accendere l'alimentazione di riscaldamento per riscaldare uniformemente la testa della macchina e la macchina Jane. Allo stesso tempo, aprire l'acqua di raffreddamento sul fondo della tramoggia e della scatola ingranaggi e la valvola di ingresso dell'acqua della pompa del vuoto di scarico.

I macchinari Baoshen ti offrono un servizio di alta qualità