粘土レンガ移動式トンネル窯

移動式環状トンネル窯の複数の重傷

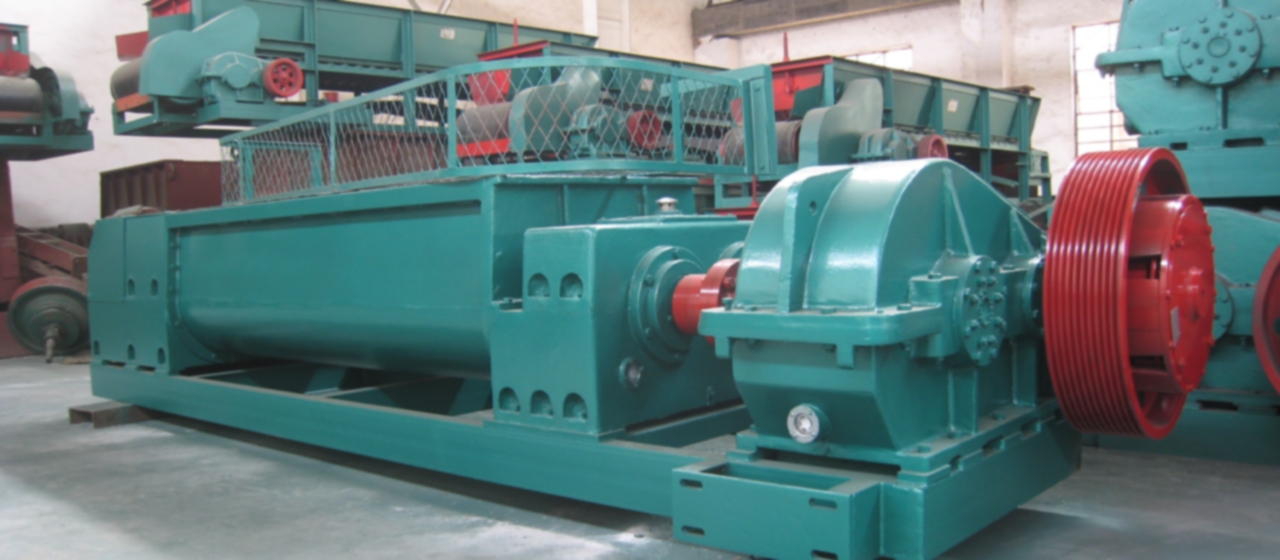

The structure and production process characteristics of mobile circular tunnel kilns are different from general tunnel kilns. They have relatively less investment, shorter construction time, lower production costs, and lower calcination energy consumption compared to general tunnel kilns. They have developed rapidly in the past decade. しかし, in practical use, the effect is not satisfactory, and there are many defects and problems. Some are inherent structural and quality issues, some are process issues limited by the characteristics of this type of kiln, and some are environmental issues, ultimately affecting the output and quality of products. Most mobile circular tunnel kiln manufacturers have poor product quality and high scrap rates. There are multiple reasons for this “problem kiln”, first of all, the mobile circular tunnel kiln itself has some serious problems and defects, and there are several difficult to treat hard wounds:

1. Mobile circular tunnel kilns are not suitable for use in cold winter areas in the north.

The four main processes of brick stacking, drying, roasting, and unloading in this type of kiln are arranged on the circular kiln passage, and operate in a sequential cycle with the circular kiln passage. There are no heating and insulation facilities, and production is mainly carried out in outdoor natural environments. Only rainproof and sunscreen awnings are installed on the kiln. したがって, during the winter frost period in the north, the mud in the conveyors, mixers, and brick machines of this production line will be frozen into hard blocks and unable to be produced. Especially the wet billets stacked on the circular kiln, which have long been frozen hard and unusable, will definitely be shut down.

Affected by the cold climate, the effective working period of the mobile circular tunnel kiln is only 6-8 months per year, which cannot reach the total annual output. Anyone who chooses this kiln production line in the cold winter regions of the north has seriously affected the output and quality of the products. Its so-called advantage of high output has become an empty statement, leading to poor overall economic benefits throughout the year.

2. Mobile circular tunnel kilns have special requirements for the construction site.

Because its kiln body is a circular arc ring shape, it is placed on two concentric but unequal diameter circular tracks. 窯の断面は幅13m以上, 4.5mを含む, 6.5メートル, 8.8メートル, そして10.m8. その建設用地は、ワンタイムコード燃焼トンネルキルン生産ラインの同じ生産規模に使用される土地と同様です。. しかし, 移動式円形トンネルキルンの生産ラインには厳しい現場条件が必要です, サイト選択の適応性が低い, 全体的なプロセス設計の柔軟性が制限される. 1 つは、敷地が十分に広い広場である必要があることです。 (円形), and the other is that the site must be flat and even level, without the flexibility and adaptability of a typical tunnel kiln production line.

3. Does not meet the requirements of relevant environmental standards.

① The height of the exhaust funnel (chimney) for drying and roasting waste gas emissions does not meet environmental standards. The moisture exhaust fan and smoke exhaust fan of the mobile circular tunnel kiln are all installed on the moving kiln and move with the kiln. All fans are not vertically upward, only the exhaust pipe is installed horizontally, allowing the exhaust gas to be discharged towards the inner side of the circular tunnel through a section of horizontal exhaust pipe. As a result, the exhaust gas diffuses around the factory area, creating a foul atmosphere that not only harms workers but also causes serious pollution to the environment. Some manufacturers have been continuously protested and complained about by surrounding residents, 地元の環境保護局から生産の停止と是正を命じられています。.

②乾燥・焙煎時に発生する排ガスを処理していない. 移動式円形トンネルキルンの焼成物に使用される燃料は石炭です (石炭ギャング, スラグ, 等), 燃焼により発生する排ガスには煙や粉塵などの粒子状物質が含まれています。, SO2 などのガスも, HF, NOx, CO2, 等, 排ガス浄化等の措置が施されていないもの, 除塵, 脱硫, 重大な汚染を引き起こす.

4. Thermal system and drying and roasting thermal process issues of mobile circular tunnel kiln.

① The quality of drying is difficult to guarantee, and uneven drying and dehydration may occur due to climate changes such as season, day and night, sunny and cloudy, cold and warm, dry and wet, which can easily lead to network cracks or mute sounds in the product.

② Due to the integrated connection and movement of the drying chamber and calcination kiln in this type of kiln, ビレットの乾燥速度は仮焼窯の焼成速度によって制限される, ビレット乾燥プロセスの要件に応じて調整および制御することはできません。. 仮焼窯に入るビレットの温度が高すぎるか低すぎる, 残留水分が高すぎるか低すぎる, 製品に亀裂が入ったり、音が鳴らなくなる可能性があります。.