Product Introduction:

The energy-saving and high-efficiency assembled tunnel kiln produced by Baoshen (Group) adopts steel structure, kiln inner wall and flat ceiling, adopts high-temperature light insulation mullite brick (board), and the inner layer is assembled with high-temperature resistant fiber cotton. Factory manufacturing, on-site combined installation of new technologies, dry manufacturing of non rotten kilns, with short construction cycle, high thermal efficiency, solid, gas and liquid fuels can be used, which is convenient for transportation and overall relocation of the production line. The digital management technology of kiln operation and temperature control has greatly improved the production efficiency and product quality.

The kiln is divided into three parts: preheating section, roasting section and cooling section. These three parts not only have independent functions, but also cooperate with each other. In the smoke exhaust system of the preheating section, the smoke extracted by the smoke exhaust fan enters the separation box, the smoke is purified and discharged, and the gas is sent to the roasting section for combustion support through the pipeline. The roasting section is equipped with a gas generator to supply gas, which saves 25% on average compared with coal roasting, and the combustion is complete without emission. The waste heat in the cooling section is used as the heat source for drying bricks and employees’ life, saving energy and environmental protection.

Advantages:

Factory manufacturing, on-site combined installation of new technologies, dry manufacturing of non rotten kilns.

1 .Assembled modular tunnel dryer and kiln ,factory manufacturing technology

2 precision fast, energy-saving heat cycle, assembly Tunnel kiln, the modular design and factory manufacturing technology.

3.The assembly type tunnel kiln, drying chamber operation control coupling technology and integrated technology demonstration.

4 Assembly type tunnel kiln for different materials and products of drying, firing technology and demonstration.

5 The assembly type tunnel kiln and fast firing brick and tile of the thermodynamics and gas dynamics simulation and design

6. Assembly type tunnel kiln decomposition, relocation, fast connection assembly technology and demonstration.

Product Parts:

Alloy mixer blades |

Alloy hollow brick mould |

Alloy brick mould |

Auger |

Thrust bearing |

Reducer |

| Auger adopts high chromium raw materials,the auger front part can produce 25million bricks,the auger back part can produce 45 million bricks one time. | High load capacity to admit any pressure from soft to stiff extrusion condition. | Reducers with parallel shafts,case hardened and ground helical gears to ensure secure,progressive transmission and quiet operation and long durability. |

Extruder shaft |

Liner |

| Extruder shaft and gear adopts heat treatment.If with proper maintenance,we can give at least 4 years guarantee for gears and shaft. | 1.Hinged body.Easy opening for maintenance tasks and part replacement.

2.Highly wear resistant chrome alloy liners with a bolt-free system,preventing air leaks and making replacement operations easier. |

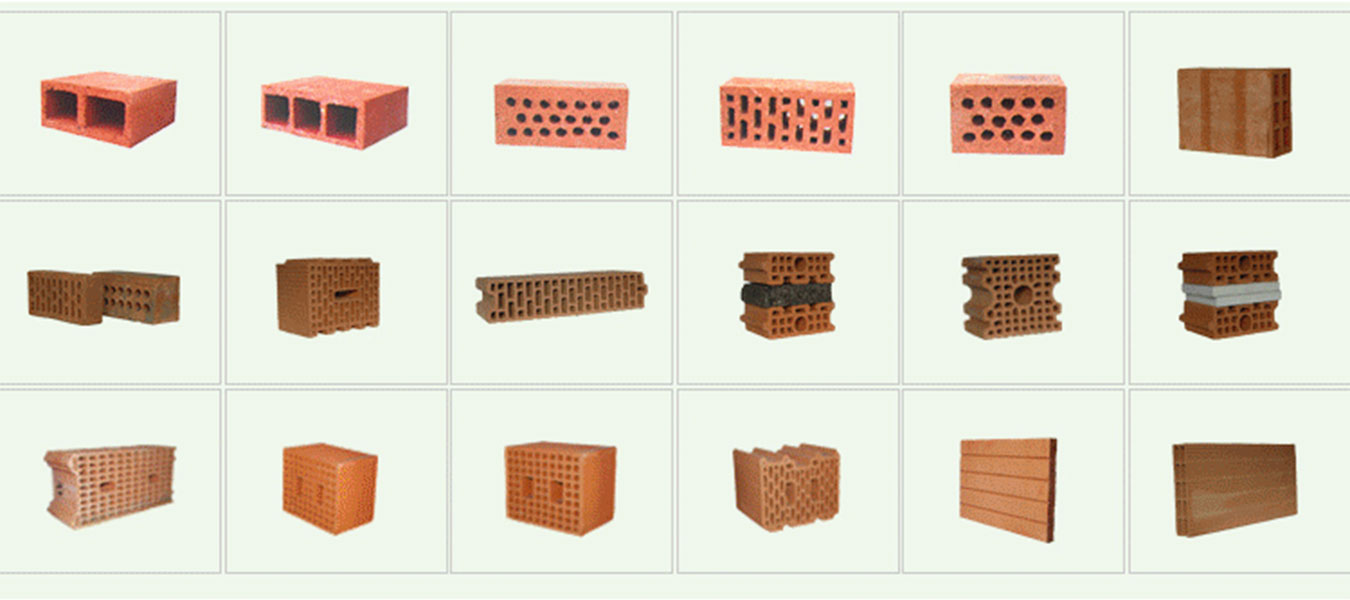

Making different bricks: