china brick factories

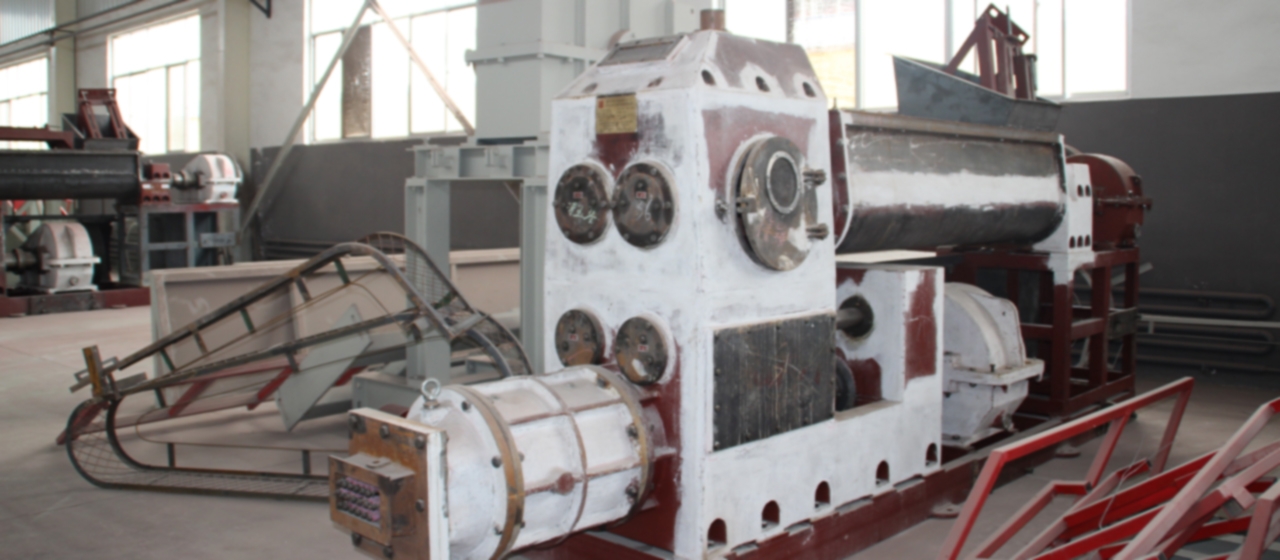

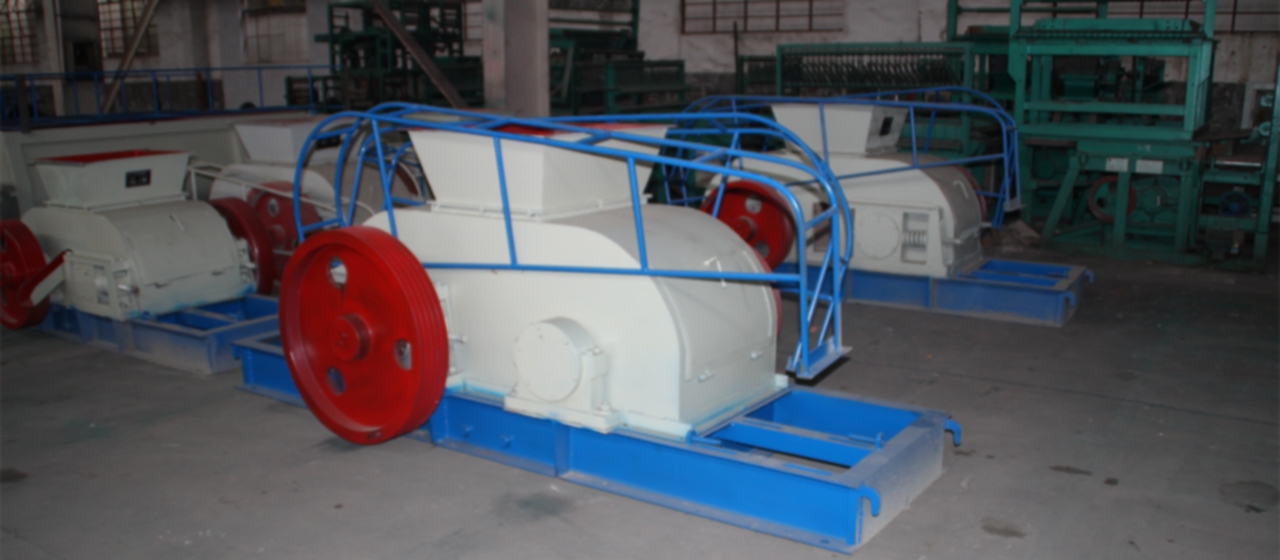

It can utilize raw materials such as all coal gangue, all shale, and high content fly ash, and is suitable for brick factories with an annual production capacity of over 60 million standard bricks. It is also an ideal equipment for producing exterior wall decorative bricks, clear water wall bricks, and other products. The newly developed equipment of this machine series has the characteristics of high extrusion pressure, high output, low motor power, and double mud strip semi hard plastic extrusion molding. Adopting the advantages of advanced equipment at home and abroad in design, with stable and reliable performance, and convenient operation and maintenance; In terms of price, it is much lower than imported similar equipment and has a good performance price ratio.

The machine is equipped with various types of cutters, multiple sets of hollow brick machine mouth molds, and designed with multiple speeds. Technical parameters can be adjusted according to different soil types and raw materials, and it has a wide adaptability. Its extrusion part is double mud strip semi hard plastic molding, and the output of standard bricks can reach more than 20000 pieces/hour. This function meets the needs of brick factories at different levels and is an ideal equipment for users to build and upgrade.

[Maintenance and Overhaul]

1. Regularly pay attention to and adjust the clutch, and strictly prohibit any looseness or tightness. Check the air pump

Is the air pressure normal.

2. Regularly pay attention to the load condition of the motor and measure whether there are any abnormal fluctuations in the current.

3. Regularly check the gearbox to ensure sufficient oil supply. Replace the lubrication after using the new machine for one month

Lubricate the oil once and replace it annually thereafter. Check if the bearings are heating up and if there are any abnormal noises.

4. After a certain stage of use, the spiral blade should be replaced in a timely manner depending on the wear and tear. General spiral

The gap between the blade and the mud tank shall not exceed 10 mm.

5. We should establish a system of large, medium, and small inspections and conduct regular checks.

a) The host undergoes one to two minor repairs per month, and can be repaired or overhauled during the winter season.

b) The water ring vacuum pump should adjust the clamping bolts of the packing in a timely manner and regularly replenish the packing.

6. During the use of the vacuum machine, the condition of the filtration system and the joint surfaces should be checked regularly

The sealing condition is to ensure the vacuum degree.

7. Method for removing the spindle winch:

Remove the mud head and unscrew the hexagonal bolts. If the first few sections of the winch do not need to open the Hafu cylinder, when disassembling the entire winch, first open the Hafu cylinder and then remove the floating shaft.

8. The disassembly and assembly method of the superior Hafu winch:

First, remove the upper cover plate of the mixing tank. When removing the left and right Hafu winches, remember the left and right rotation direction and position of the winches (the two winches intersect in the middle, and the tail of the blade is perfectly aligned with the mud knife and spiral line). During installation, do not install them upside down or misplaced.

9. The disassembly method of the spindle assembly is as follows:

Firstly, loosen the expansion sleeve bolt of the main shaft coupling, then unscrew the oil filling hole bolt, and then remove the 10-m20 tightening bolt at the rear of the bearing seat. Use the m24 bolt to push the main shaft assembly out of the feeding box.