clay Block Machine

1. The raw material : clay,mud,soil.

2. Brick type: solid bricks, hollow blocks.

3. Brick drying : sunshine drying or small drying room.

4. Brick firing : local brick kiln, brick hoffman kiln , brick tunnel kiln.

The bricks moisture content about 20~22%, so the bricks can stacking by automatic brick stacking machine .

The bricks drying processing :

1. Under the sunshine drying .

2. Small drying room .

3. Tunnel dryer chamber .

The clay brick firing processing :

1. Your local brick kiln .

2. Brick hoffman kiln.

3. Brick tunnel kiln .

What kind of factory can choose that type of machinery :

1. Want to produce different size and different type bricks/blocks .

2. Raw material : clay, mud, soil, fly ash,shale .

3. Brick drying : small drying chamber, tunnel dryer chamber

4. Brick firing : brick hoffman kiln, brick tunnel kiln

5. Can use automatic brick stacking machine to stack bricks

6. Full automatic brick production line brick molding machine

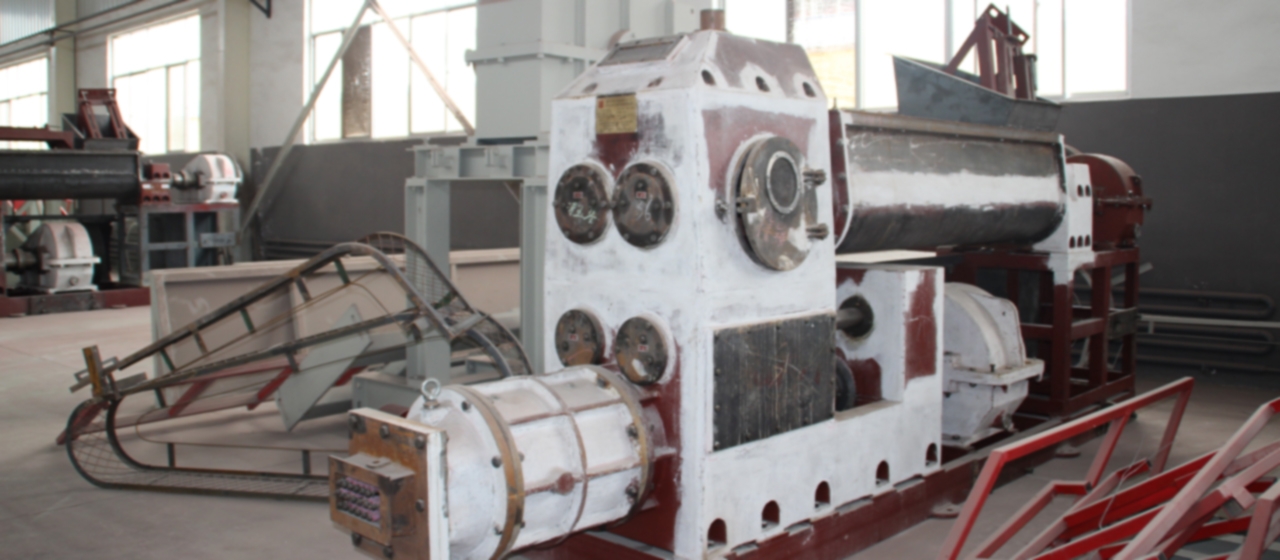

JKR vacuum extruder brick making machine technical parameters:

| Specification Model | Throughput (m3/h) | Rotate Speed of Principal Axis (turn/m) | Power Requirements (kw) | Exterior Dimension (mm) |

| JKR35/35D-20 | 7000-9000 | 32/32 | Y6-30/55 | 5040*1600*2000 |

| JKR40/40F-25 | 8000-12000 | 40/35 | Y6-37/75 | 5660*1680*2150 |

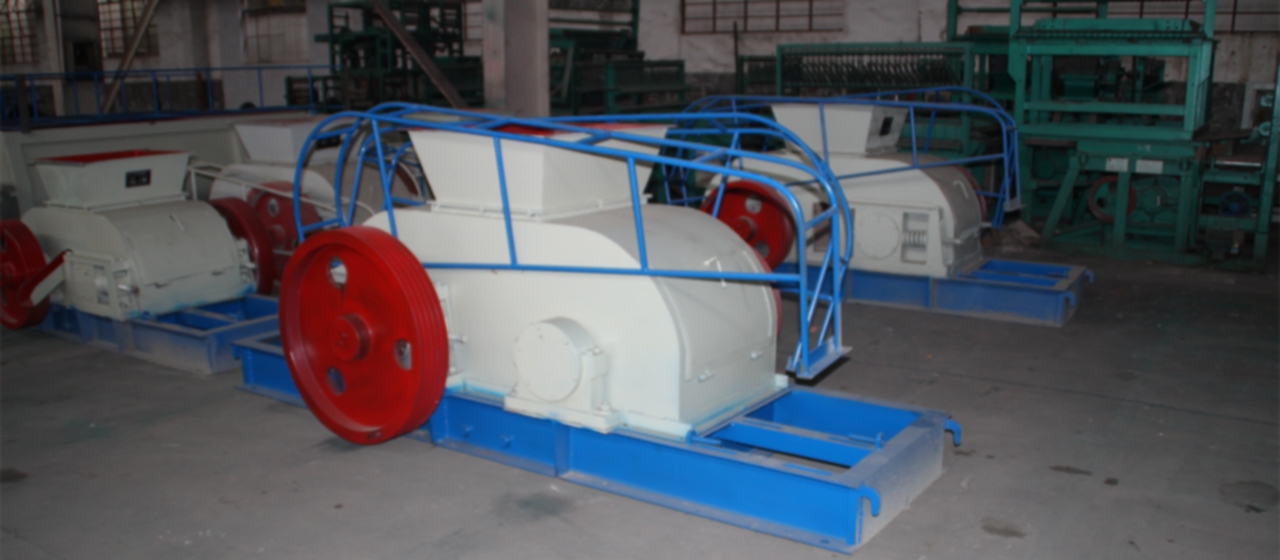

We aslo supply as following clay brick making machine and brick equipment :

Box feeder machine– belt conveyor–roller crusher–double shaft mixer– vacuum extruder– auto brick cutter –brick loading facility– brick battery cart.