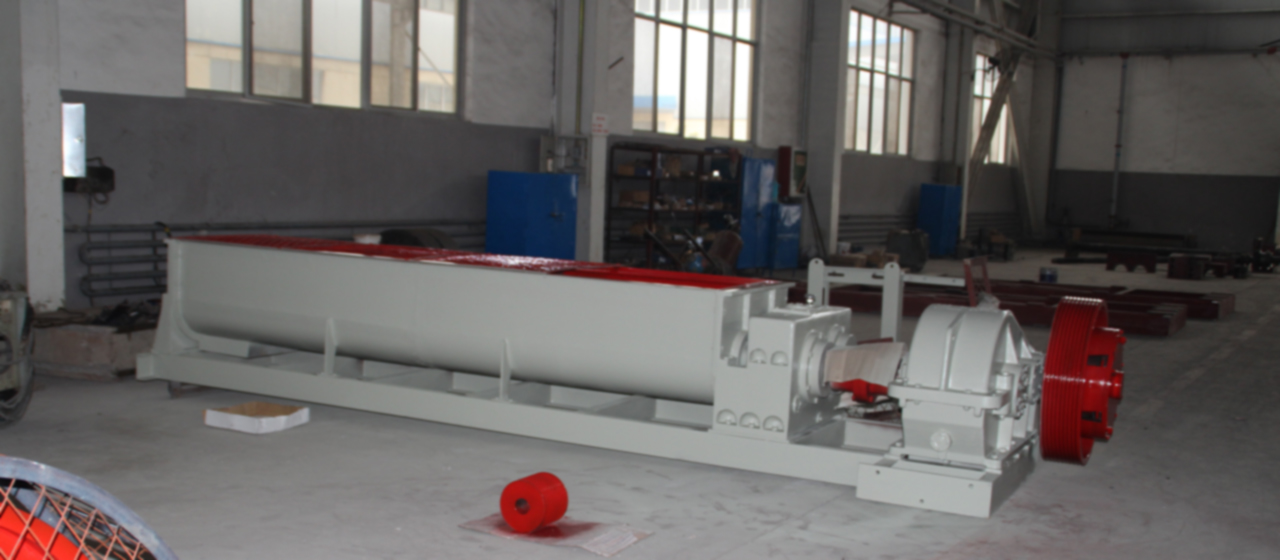

mobiler Tunnelofen

Der Ofenkörper des mobilen Tunnelofens läuft auf einer Doppelringbahn, with drying section, Vorwärmabschnitt, roasting section, insulation section, and cooling section arranged from front to back. When the kiln body moves forward, the bricks brought in from the front door of the kiln will be exposed to the outside of the kiln tail door after completing the entire process of drying, preheating, and firing with the movement of the kiln body.

Mobile tunnel kilns can flexibly choose suitable process systems based on market, capital, raw materials, geography, transportation and other conditions.

1. One time code firing, integrated with drying kiln and roasting kiln:

The biggest feature of this process is that it requires minimal labor and low energy consumption, but it requires the use of higher wet billet strength and high extrusion pressure requirements for the brick machine.

2. One and a half yard firing, integrated with drying and baking kilns;

Mit diesem Verfahren kann im Vergleich zu Ziegelmaschinen bei gleicher Ofeninvestition und geringerem Extrusionsdruck eine höhere Gesamtleistung erzielt werden, aber es erfordert ein höheres Prozesssystem, Dies erschwert die Kodierung des Knüppels, mehr Arbeit erfordern, und erfordern ein relativ hohes Maß an Management.

3. Sekundärcode-Auslösung, separate Trocken- und Röstöfen:

Hohe Produktion, aber hoher Energieverbrauch, große Logistikaufgaben, und hohe Arbeitskosten. Deswegen, Es wird nicht empfohlen, es in großem Umfang zu verwenden und sollte nur unter besonderen Umständen verwendet werden.

2. Low energy consumption, high efficiency of thermal engineering systems, good insulation effect, high waste heat utilization rate

The wall of the mobile tunnel kiln is stacked with aluminum silicate refractory fibers, which has a good insulation effect. In the practice of the experimental production line, after stopping coal and air supply for 48 Std., the kiln can still be roasted normally after re feeding coal and air supply. In use, the outer surface temperature of the kiln wall roasting section is only 42 C ˚)

In the thermal system of a mobile tunnel kiln, all the heat emitted by firing bricks has been sent to the roasting and drying sections by the air entering the kiln for combustion and drying purposes. In 2007, during the trial firing, the energy consumption was only 240-340 kcal/kg.

3. Low employment

The production line employs approximately 30-40 people:

2 bulldozers for feeding, 4 people for mixing and crushing, 2 people for brick making, 3-6 people for palletizing, 8-15 people for drying and roasting, 3 people for brick production, 6 people for human-machine repair, und 2 people for brick making

4. Small footprint

Except for the raw material storage yard, the production line only requires about 27 acres of land.

5. Smooth logistics and low labor intensity

In the production of a brick factory with an annual output of 50 million pieces, the daily logistics volume between various processes such as raw material preparation, Transport, Altern, billet making, Trocknen, and firing is about 430T × (5-8 times), most of the manpower in ordinary rotary kilns is consumed here, and the labor intensity is high, and the working environment is harsh.

Die Produktionslinie des mobilen Tunnelofen-Prozesssystems verfügt über einen mechanisierten und automatischen Logistikbetrieb. Die Arbeiter müssen lediglich die Ziegel vom Blockförderband aufnehmen und stapeln, was im Vergleich zum Be- und Entladen des Drehrohrofens recht einfach ist. Besonders, Das Arbeitsumfeld ist hell und offen, weder schmutzig noch heiß.

6. Keine Wartung des Ofenwagens, langer Wartungszyklus für Kälte- und Heißschockbeständigkeit der Öfen

6. Keine Wartung des Ofenwagens, langer Wartungszyklus für Kälte- und Heißschockbeständigkeit der Öfen

a. Der Ofenkörper kann sich bei thermischer Ausdehnung und Kontraktion frei ausdehnen und zusammenziehen. The kiln wall is stacked with aluminum silicate refractory fibers, which not only reduces the weight and thermal expansion and contraction stress of the kiln body, but also avoids furnace cracks;

b. The thickened kiln wall with redundant design can withstand longer periods of airflow erosion, thereby improving its service life and prolonging the overhaul cycle;

c. Without kiln cars, there would be no kiln car maintenance, and this alone can save about 200000 yuan in maintenance costs annually.