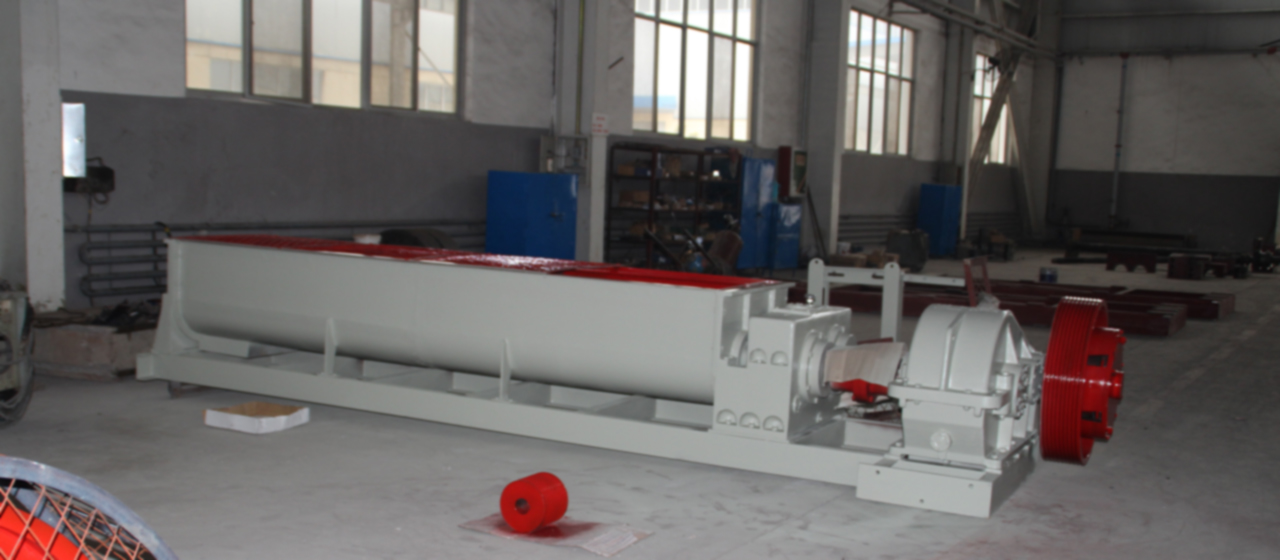

extruder clay brick machine

1)harden surface gear of Best service vacuum extruder clay brick machine was adopted in reducer, clutch are a component with own patent,without any shaking during working, even the extruder can working normal without foundation bolts.

2)the steel material of shafts and gears in Best service vacuum extruder clay brick machine are adopthigh quality carbon steel and alloy steel, the key parts are quenched and tempered treated so as to extend fly ash bricks making machine life.

3)The spiral cut reamer of Automatic Best service vacuum  adopt wear-resistance metal spray painting technology; The upper stage mixing shaft, the cut reamer big shaft, the up-down body etc. are all passed the aging, quenching and tempering process.

adopt wear-resistance metal spray painting technology; The upper stage mixing shaft, the cut reamer big shaft, the up-down body etc. are all passed the aging, quenching and tempering process.