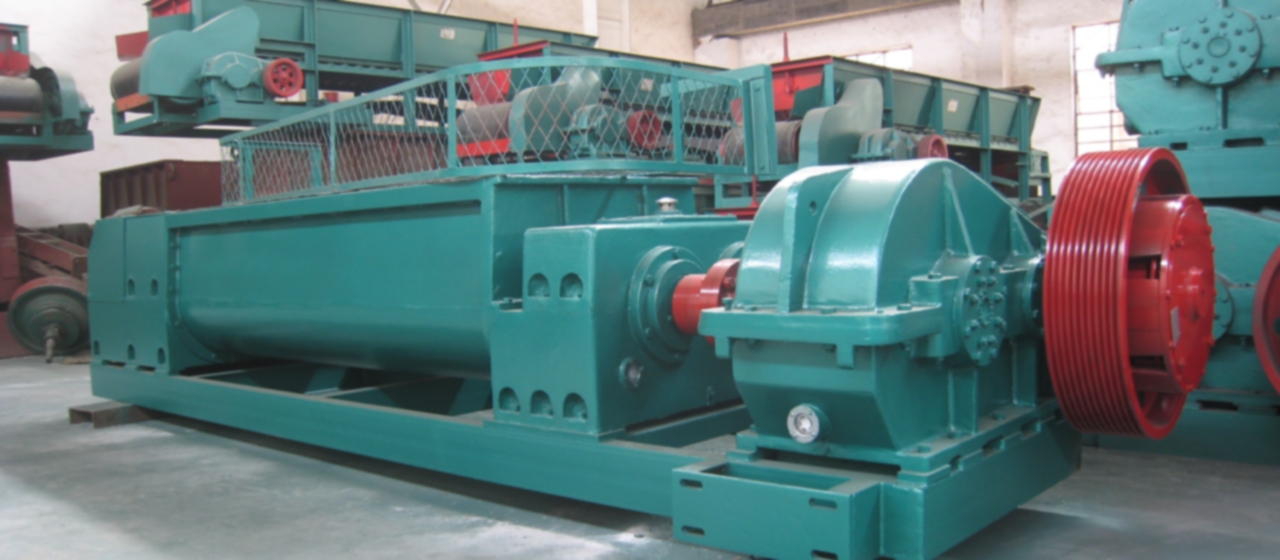

extrusion molding

The production process of sintered bricks generally consists of four parts: preparation of raw materials, shaping of the body, drying of the wet body, and calcination of the finished product.

After the raw materials for brick making are excavated, some materials can be treated by adding water, stirring, and grinding equipment, while others cannot. Raw materials such as mountain soil, coal gangue, and shale need to be crushed and finely ground before being mixed and ground with water. The selection and preparation of raw materials directly affect the quality of finished bricks. Therefore, it is often said that raw materials are the foundation of producing sintered bricks, indicating the importance of raw materials and their preparation.

After the selected raw materials for brick making are prepared and processed, they enter the molding workshop for molding. In China, the green body molding method for wrapped bricks is basically plastic extrusion molding, and there are three methods for plastic extrusion molding, namely plastic extrusion molding; Semi rigid plastic extrusion molding and rigid plastic extrusion molding.

These three extrusion molding methods are distinguished based on the difference in molding moisture content. When the moisture content of the wet preform is greater than 16% (all below dry basis are dry basis), it is plastic extrusion molding. When the moisture content of the wet billet is 14-16%, it is semi hard plastic extrusion molding. When the moisture content of the wet billet is 12-14%, it is a hard plastic extrusion molding.

The green body forming includes: the feeding, mixing, water addition, and grinding equipment processing part before the raw materials enter the forming workshop and the extrusion molding brick machine; After passing through the brick molding machine, qualified mud strips and wet blanks are formed. Forming requires achieving the shape and structure of the product, which constitutes the shape and structure of the product.

Therefore, it is often said that forming is the foundation. That is to say, the required external shape and structure of the product are formed through molding. Forming is the fundamental meaning in the brick making process. Because the quality of the formed body is directly related to the appearance quality of the finished bricks.

After the wet billet is formed in the molding workshop, it needs to be dehydrated and dried. In the production process of sintered bricks, there are two ways to dry the wet body: natural drying and artificial drying in a drying room.

The use of natural drying for wet billets involves stacking the wet billets on the embankment of the natural drying site, and manually placing them on inverted flower racks. The wet billets are then naturally dried using the atmosphere, allowing them to cool and sun dry.

Wet billet is dried manually, with an artificial drying room for wet billet drying.

Artificial drying rooms are divided into three forms: large section tunnel drying rooms, small section tunnel drying rooms, and chamber drying rooms for manual drying of wet billets. These three drying methods, regardless of which one is used, all involve manually or mechanically stacking wet billets onto a drying truck. At this point, the drying truck that has been stacked into wet billets will enter the drying room to dry the wet billets.

The hot medium in the drying room usually comes from the waste heat of the sintering kiln or the hot air furnace. Regardless of the drying method and manual drying form used, wet billet drying must follow the principle of ensuring that the billet does not deform or crack during the drying process.

If there are problems with the appearance quality of the product during drying, the waste rate is high, the output decreases, the cost of finished bricks increases, and the economic benefits of the enterprise are naturally not good. Therefore, it is often said that drying the green body is a guarantee. This indicates the importance of wet billet drying in the brick making process. After drying, when the residual moisture content of the wet billet is less than 6%, the billet is sent to the roasting kiln for firing.

The commonly used kiln types for roasting are rotary kilns and tunnel kilns. When using rotary kilns for roasting, bricks are manually stacked in the kiln passage to form stacks. Fire runs in the kiln for roasting. When using a tunnel kiln for roasting, bricks are manually or mechanically stacked on the kiln car to form piles. The kiln car with the stacked bricks enters from the tunnel kiln head and exits from the kiln tail, and the bricks on the kiln car are roasted into bricks. The roasting flames in the kiln do not run, but instead, the kiln is loaded with billets and fired with brick stacks running inside the kiln.

Regardless of whether using a rotary kiln or a tunnel kiln for firing bricks, it is necessary to ensure that the bricks are not burned under fire and become unburned bricks; Secondly, bricks should not be burned too much, roasted too much, or turned into burnt bricks. Therefore, it is often said that roasting is the key in the production process of brick making, and the proportion of roasting in the brick making process is clearly stated.

The four important components of the process of sintered bricks can be summarized as follows: raw materials are the foundation, forming is the foundation, drying is the guarantee, and roasting is the key. These four parts are interdependent.