fully automatic red brick machinery

1.Reducing raw material moisture, lower drying cost

2.It is suitable for making different sizes of clay brick, blocks etc.

3.It is suitable for low, medium and high plastic raw material

4.It is suitable for fully automatic once and twice stacking ,therefore simplifying production chart, saving investment

5.Finished product with higher density and higher strength,not easy to be damaged while packing ,transporting and

construction.

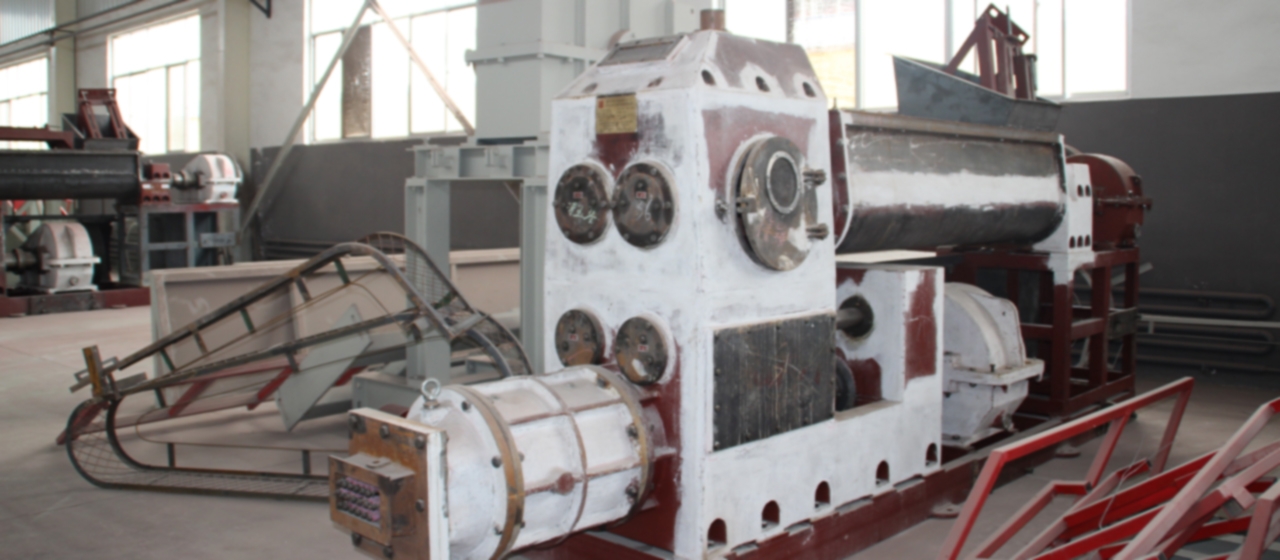

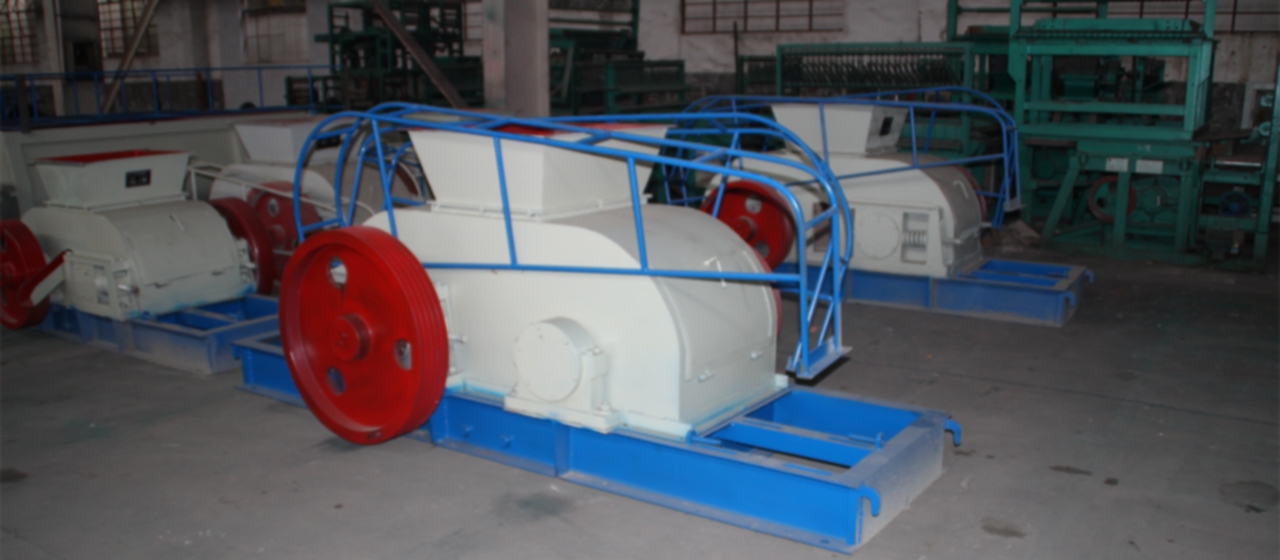

Our company’s products include raw material feeding, mixing, crushing systems, hard plastic and semi-hard plastic extruders, automatic brick cutting and transportation equipment, tunnel kilns , rotary kilns ,roller kiln, shuttle kiln etc.

| Auger Auger adopts high chromiumraw material, the auger frontpart can produce 20 millionbricks, the auger back partcan produce 40 million bricksone time. |

Thrust bearing High load capacity to admitany pressure from soft to stiffextrusion condition |

Reducer Reducers with parallel shaftscase hardened and groundhelical gears to ensuresecure, progressive transmission and quiet operation and long durability. |