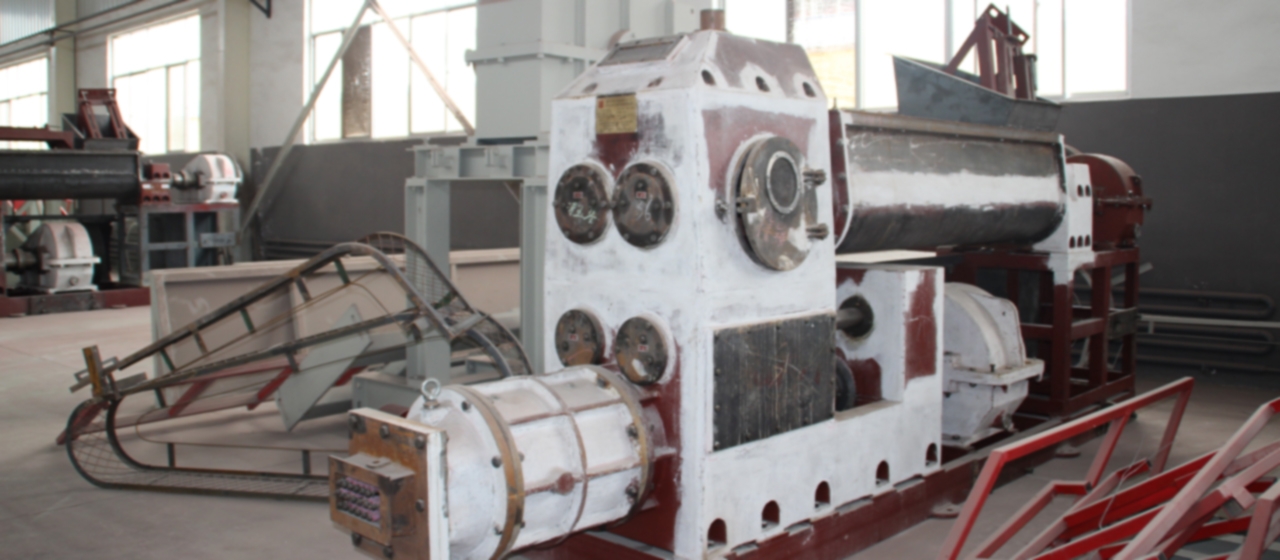

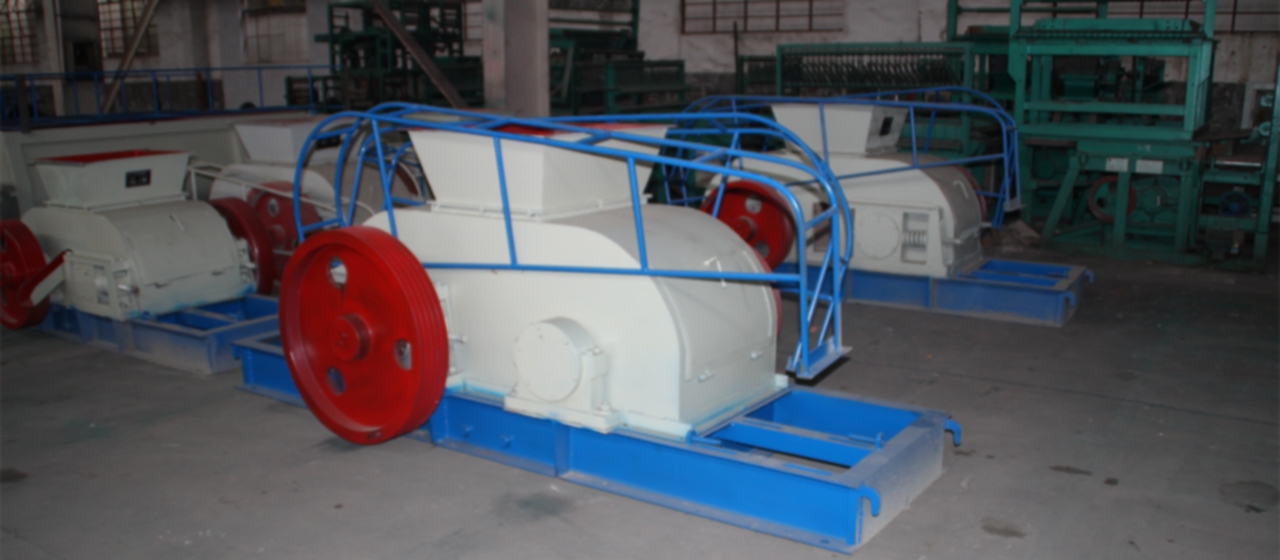

hollow brick Vacuum extruder

Vacuum extruder

The red brick machine, also known as the vacuum extruder, adopts the principle of single machine extrusion, uses an electric motor, and drives the upper mixing and lower extrusion parts synchronously through an axial pneumatic clutch and a reducer. The entire machine is made of all steel structure, and the body is welded from steel plates. It is a single axis, single mud cylinder, and single spiral coaxial sealing mechanism. All reducers are hard toothed gears. The cutter adopts wear-resistant material spray welding technology, which is easy to maintain and sturdy and durable. Suitable for producing hollow bricks from shale, coal gangue, high content fly ash, and poor plasticity raw materials.