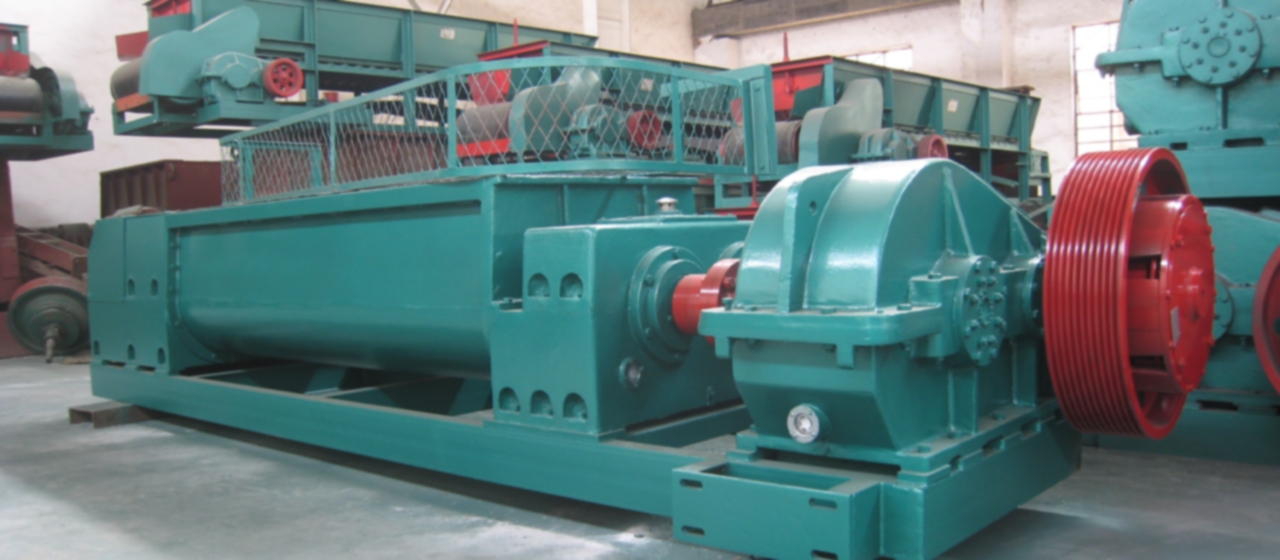

JKY60/60 large-scale brick machine

JKY60/60 large-scale brick machine is a two-stage vacuum extruder specially designed to produce perforated brick. The double strip design craft, uses the vacuum to squeeze out, the two-stage agitation, two electric motors bring along divided reducer through the axial air operated clutch , actuate the agitation to squeeze out separately and squeeze out with the formation. The machine applies to pages of rock, coal gangue, fly ash as raw materials to produce high holes rate of hollow bricks. Through quenching and tempering,quenching,heat treatment and other crafts and universal joint connector, the reducer with the independent all steel structure, improves the stability of performance and service life very effectively.

JKY60-60 Double-Stage Brick Machine(with 2 mud-strip outlets)

| Type/technical parameters | Production capacity(KPI,piece/h) | Allowable pressure(mpa) | ||

| JKY60/60-4.0 | 22000-25000 | ≤4.0 | ||

| Vacuum degree(mpa) | Motor power(kw) | Appearance size(LxWxH,mm) | Weight(kg) | |

| ≤-0.092 | 110+280 | 5400X5000X2900 | 28500 | |