Product Introduction:

- Strong applicability, high output. Good choice for big project;

- The raw material for making bricks can be clay,fly ash,coal gangue,shale,urban construction waste,gangue waste,inferior soil,etc

- High vacuum and pressure extrusion,can make strong solid bricks and hollow bricks with qualified holes.

- The size of solid brick and the holes of hollow bricks can be changed according to your needs.

- This model is hot sale in Africa,Central Asia,Bangladesh, Egypt, Saudi Arabia, Algeria ,etc.

There are two kinds of kiln for you to choose: tunnel kiln, hoffman kiln. Hoffman kiln with tunnel dryer is also good for this production line. (cost less than tunnel kiln and more efficient than hoffman kiln) If you want to learnmore information, please contact us.

Product Parts:

Alloy mixer blades Alloy mixer blades |

Alloy hollow brick mould |

Alloy brick mould |

Auger |

Thrust bearing |

Reducer |

| Auger adopts high chromium raw materials,the auger front part can produce 25million bricks,the auger back part can produce 45 million bricks one time. | High load capacity to admit any pressure from soft to stiff extrusion condition. | Reducers with parallel shafts,case hardened and ground helical gears to ensure secure,progressive transmission and quiet operation and long durability. |

Extruder shaft |

Liner |

|

|

1.Hinged body.Easy opening for maintenance tasks and part replacement.

2.Highly wear resistant chrome alloy liners with a bolt-free system,preventing air leaks and making replacement operations easier. |

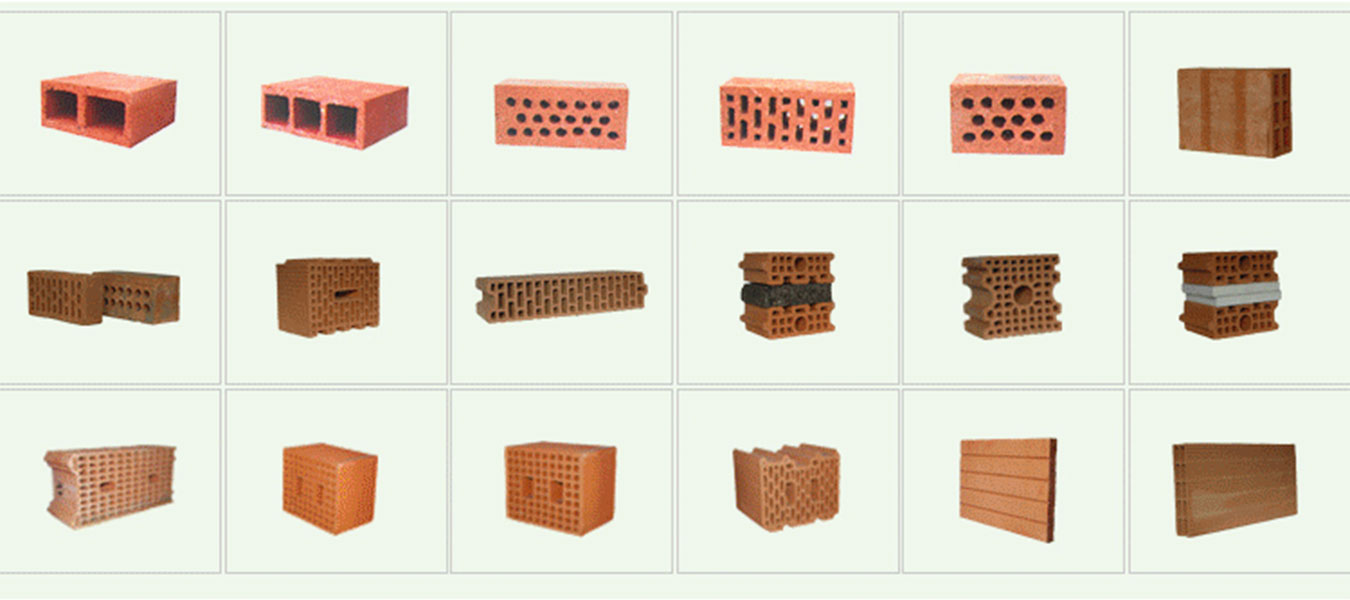

Making different bricks: