Product Introduction:

Semi-AutoMechanical structure, worker need to press the button to contron the cutter.The cutting steel wire of the slitter is pneumatically tightened, and the tension of the steel wire can be adjusted according to different products, which not only achieves the effect of sharp steel wire cutting and neat section, but also improves the service life of the steel wire.

Advantages:

simple structure,Low cost,delivering a high (8%-30%) moisture content of raw materials,the most widely used clay cutter machine.

Product Parts:

Alloy mixer blades |

Alloy hollow brick mould |

Alloy brick mould |

Auger |

Thrust bearing |

Reducer |

| Auger adopts high chromium raw materials,the auger front part can produce 25million bricks,the auger back part can produce 45 million bricks one time. | High load capacity to admit any pressure from soft to stiff extrusion condition. | Reducers with parallel shafts,case hardened and ground helical gears to ensure secure,progressive transmission and quiet operation and long durability. |

Extruder shaft |

Liner |

| Extruder shaft and gear adopts heat treatment.If with proper maintenance,we can give at least 4 years guarantee for gears and shaft. | 1.Hinged body.Easy opening for maintenance tasks and part replacement.

2.Highly wear resistant chrome alloy liners with a bolt-free system,preventing air leaks and making replacement operations easier. |

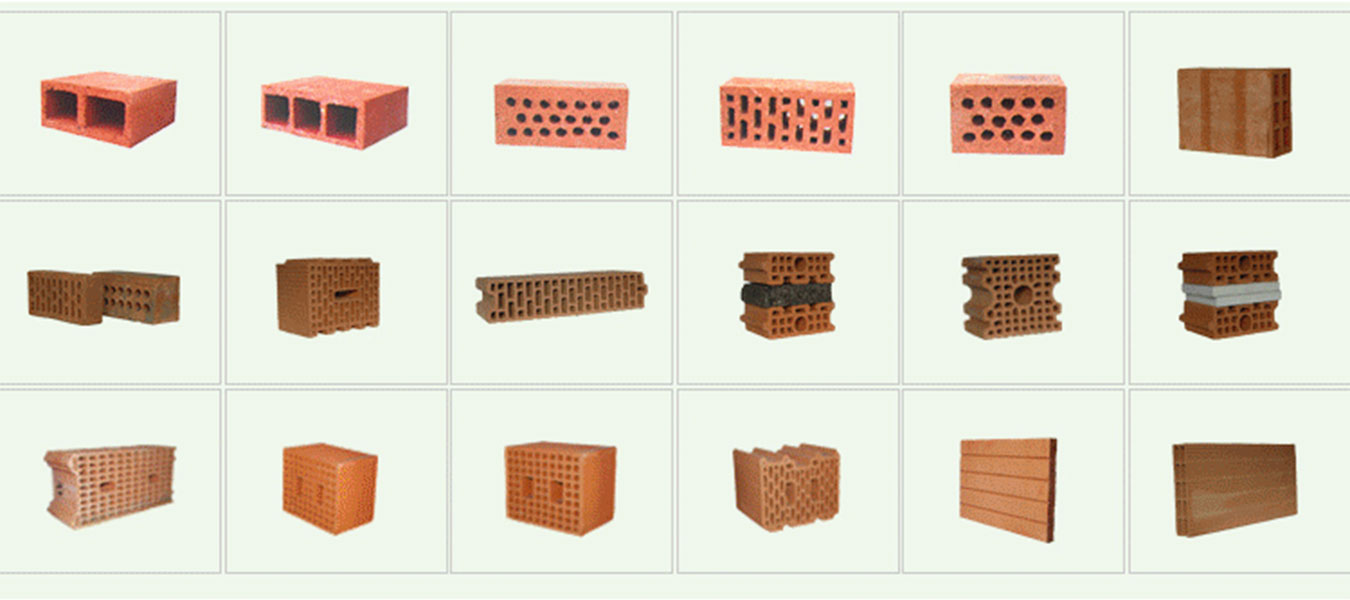

Making different bricks: