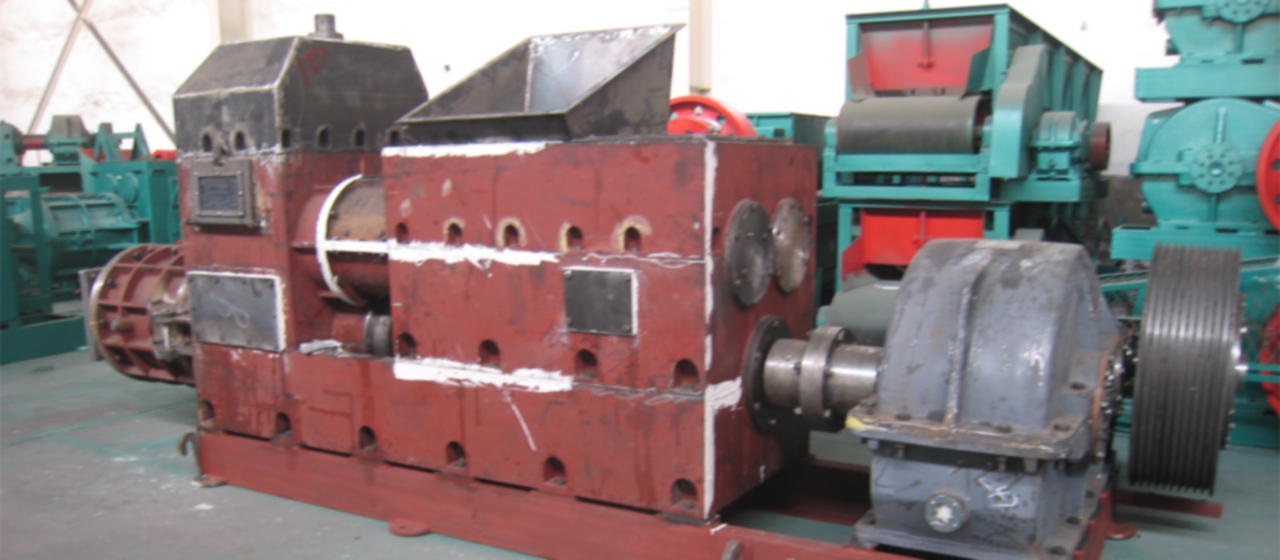

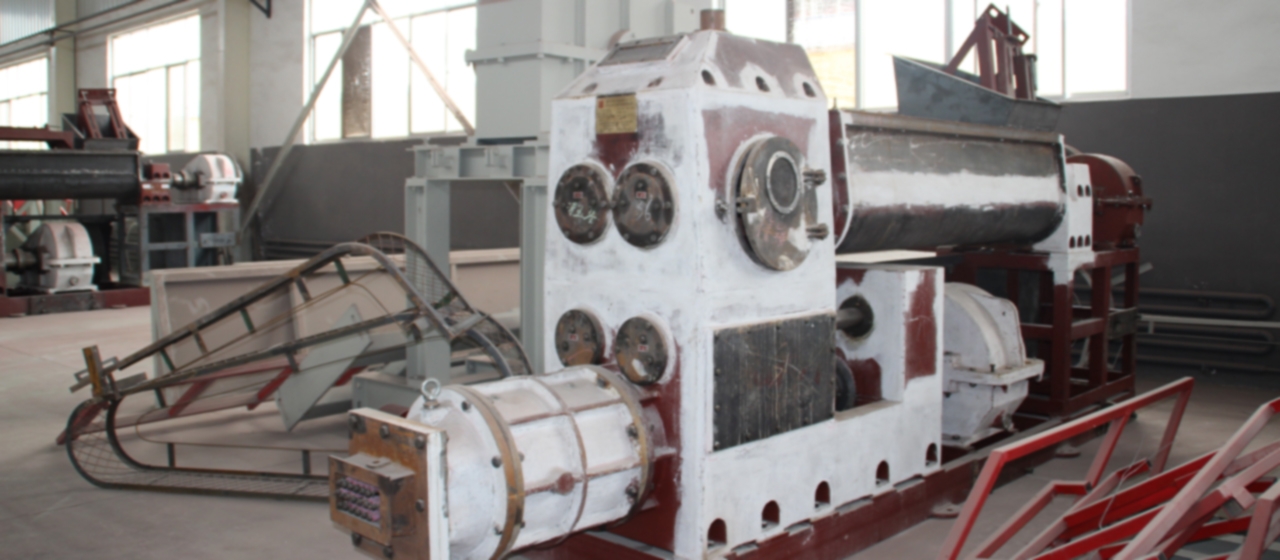

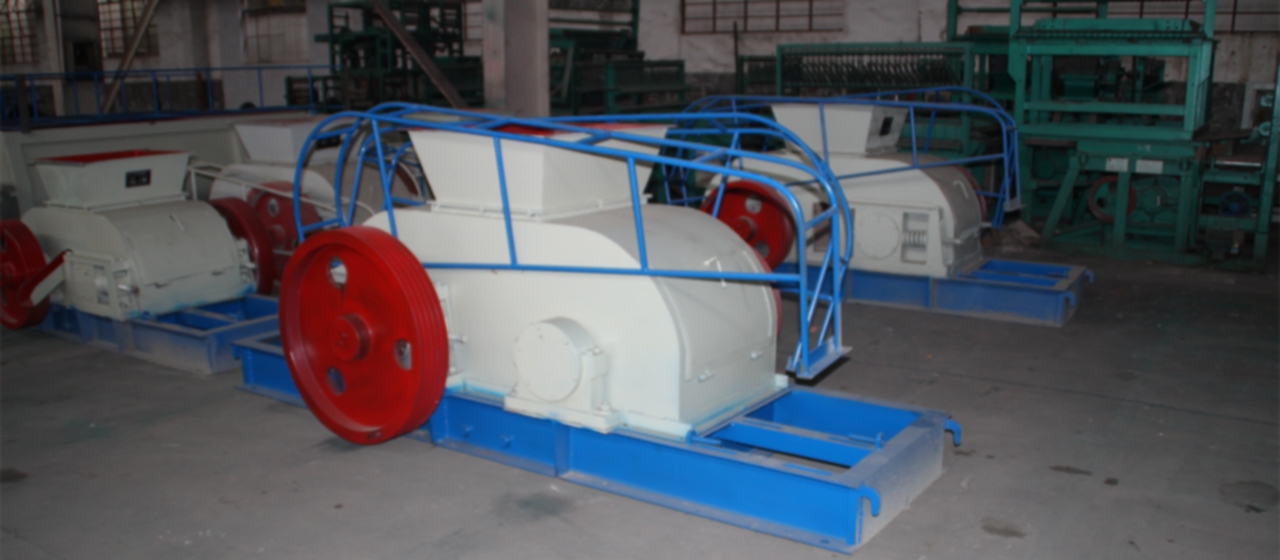

red Brick Extruder

Due to the different raw materials, The Brick Extruder can be divided into 2 main different type: Stiff extrusion and Semi-stiff extrusion. Our extruder belongs to Semi-stiff and is special designed for the soft clay, it‘s more suitable for the country like Bangladesh and India where use pure clay in high moisture content. Our extruder is high-performance vacuum extrusion equipment for forming of various type solid bricks and hollow blocks made from clay or clay mixture with coal gangue, shale, coal dust and other solid wastes. It is designed to be produced with German KWS technology according to German standards and is authorized to use German trademark of GFK. Its mixing reducer and extrusion reducer is equipped with hardenedgears which are all grin. ded. cl

ded. cl