red mud clay hollow automatic brick making machinery from china

Build best Clay brick making factory with dryer

Adopt nature dry&hoffman kiln and mechanical production process of second setting & burning.

1. Raw material & fuel preparation and handling

2)Preliminary crushed material is conveyed to twin-shaft mixing machine for adding water and agitating through belt conveyer.

3)After mixing of the first working procedure, the raw material is again sent to intense agitation extruder and high speed fine pulverizing double roll grinder for supplement water and agitating the raw material.

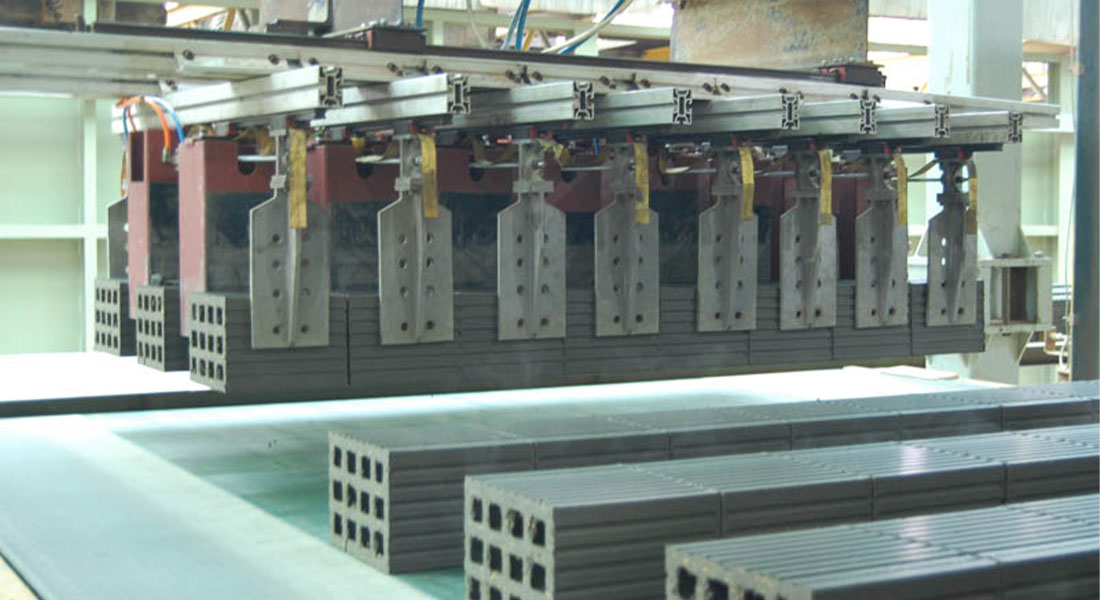

2. Molding

1)The molding water content rate should be controlled within 16%-18%.

2)The vacuum pump will take out the air that entered into the extruding machine together with pug. The vacuum extruder will extrude the pug from machine mouth and then, carry out slitting & parting according to the required dimension.

3. Drying

1)When the unfired bricks cut by cutter and arranged into groups, they are set by manual onto the dryer cart.

2) The drying chamber work system has heating system, regulating system and moisture excluding system. The drying quality is controlled by regulating system.

4. Burning

1)After drying , the unfired bricks are sent onto hoffman kiln by the dried brick cart, workers stack the bricks into the hoffman kiln for burning.

2)The properly burned bricks are sent onto the Finished brick cart by workers.

Build best Clay brick making factory wtih dryer area

The plant floor area is not less than 16,000m2.

The building area is not less than 1,300m2.