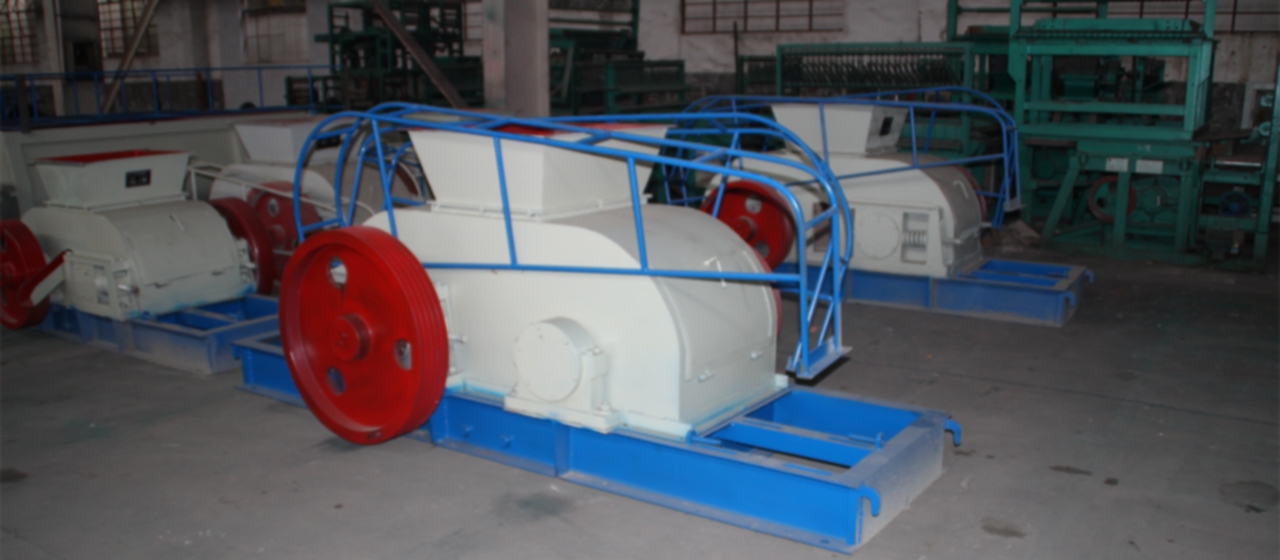

roller crusher clay brick making machinery

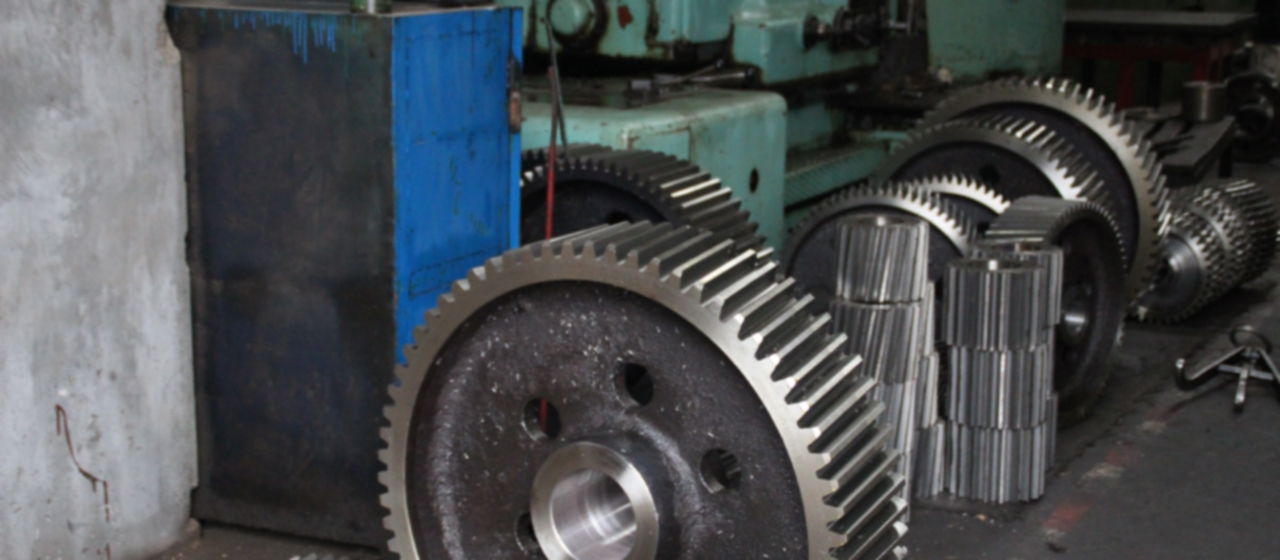

We have supply three kinds of alloy roller crusher ,

- Withsmooth alloy rollers function is same as common roller crusher but more durable.

Alloy roller hardness HRC48~55.

- Withalloy teeth which can crush stones bellow 4 cm .

- Alloy roller with groove which can remove stones from 4 ~20 cm so as to extend roller working life.

-

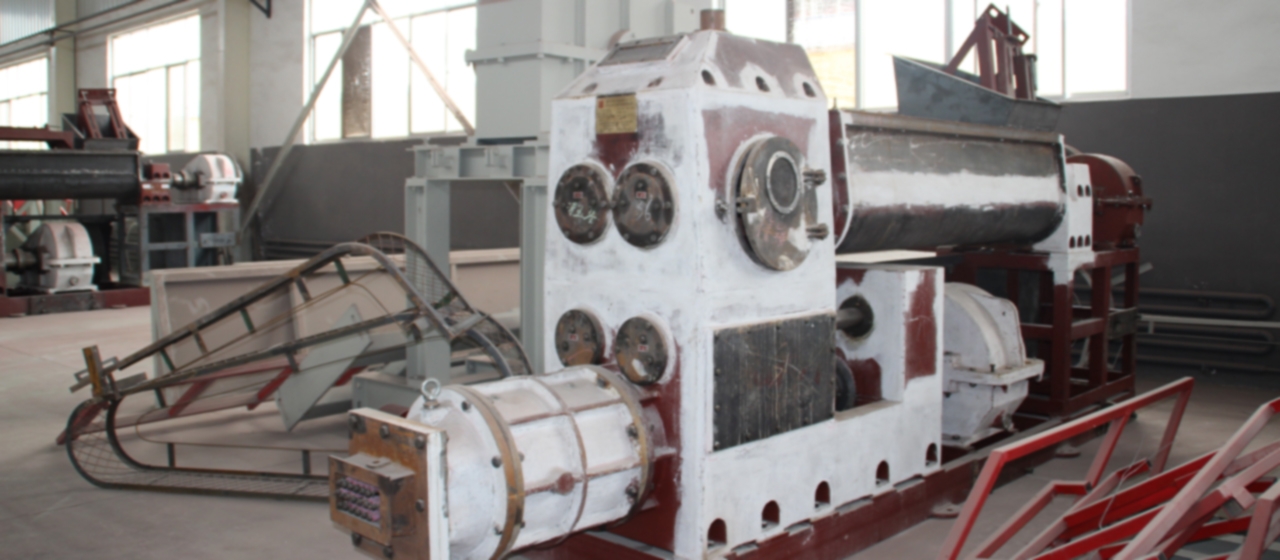

Fine pulverizing double roller crusher is used to further crush clay and other medium hard raw material into materials with the size ≤2mm.Both ends of the fine crusher are equipped with regulating pinched security block which is used to protect rolling circle and equipment.

The roller body adopts medium-manganese nodular cast iron .Hardness value may reach HRC60~62°.

The equipment is with two augers which can cut and even soil .