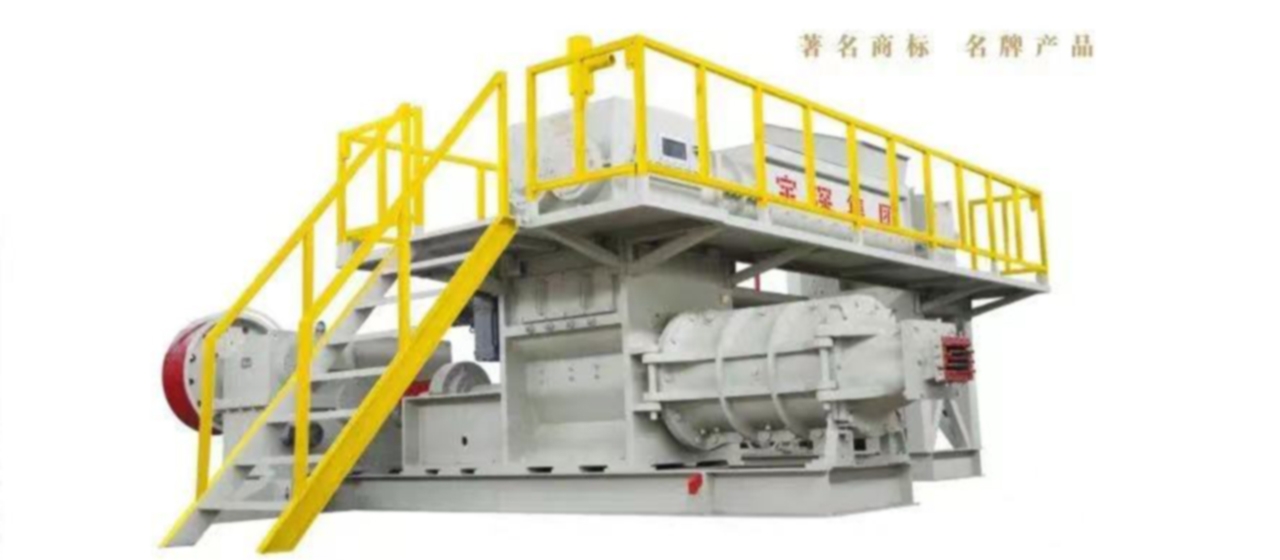

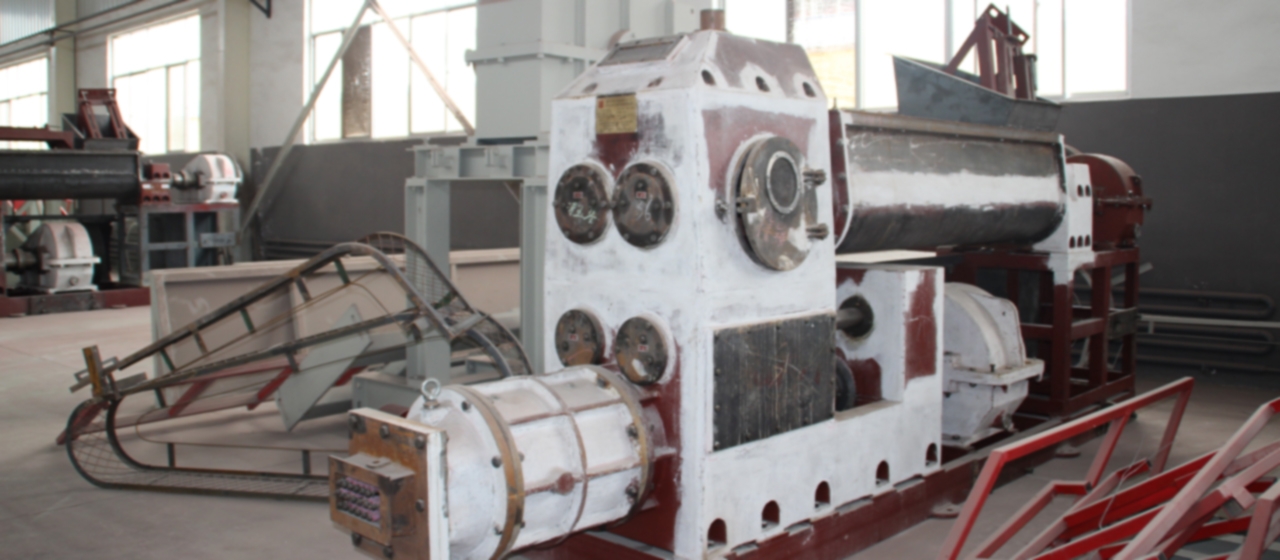

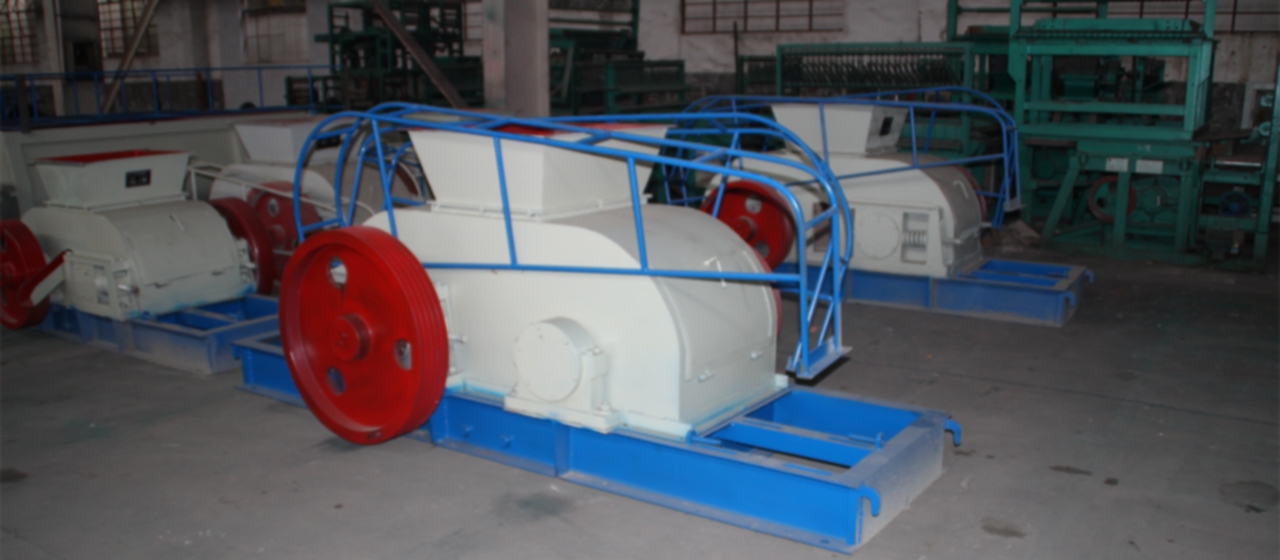

two-stage vacuum extruder

two-stage vacuum extruder

This series of models has an integral rigid connection design and high-strength alloy casting

Adopt the patented technology of gas and oil sealing separation invention

The biggest feature of the extruder is high output, low energy consumption, and higher extrusion pressure than similar products

Large extrusion pressure, strong load bearing capacity, high vacuum degree

The produced coded blanks have high compressive strength, high density and high number of coded blanks

It is suitable for one-time code firing and two-time code firing process of sintered bricks

It has a wide range of applications for raw materials, and is suitable for extrusion molding of low, medium and high plasticity raw materials

It can effectively reduce the moisture content of the formed body, thereby reducing the drying cost of the brick

Manufacture of large blocks, board walls and other products suitable for prefabricated buildings