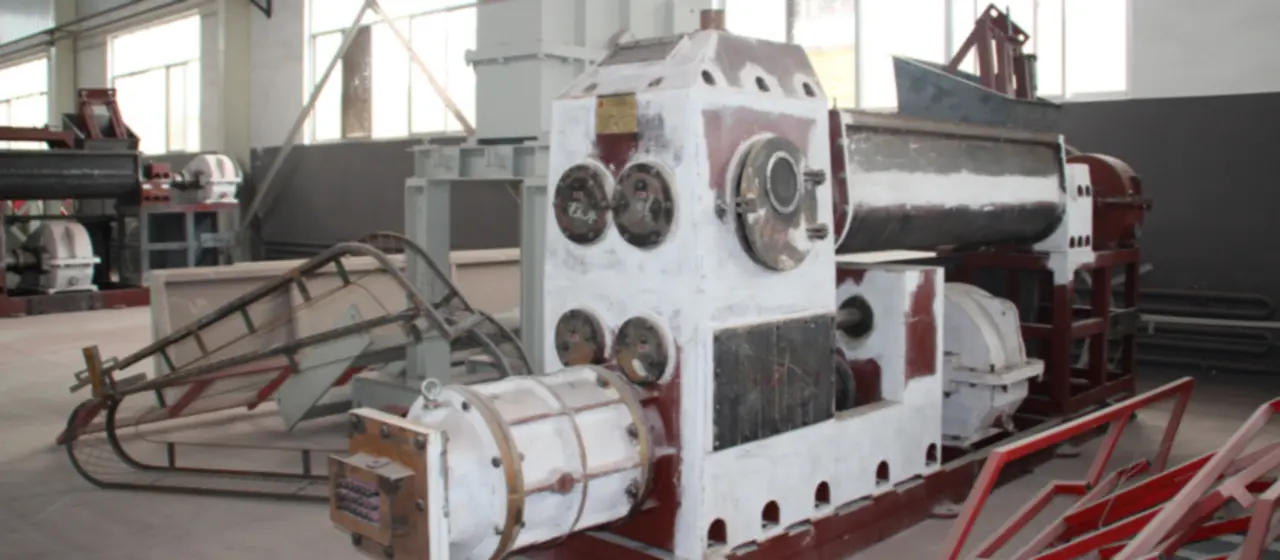

Vacuum clay brick machine

Vacuum clay brick machine, trowel adopts metal powder spraying technology; the upper stirring shaft, trowel shaft and the upper and lower body of the machine body are all treated by aging, quenching and tempering, and quenching; the gears of the reducer are all hard-toothed surfaces; the clutch The use of screw pressure technology, etc., greatly improves the service life of the equipment. At the same time, the machine has a reasonable design and compact structure, and can run smoothly without installing anchor bolts, which can greatly reduce the power consumed by the vibration during the operation of the equipment. The equipment has a multi-purpose machine, a variety of functions, and can turn waste into treasure to save energy and reduce consumption. By purchasing and using the corresponding machine head, bricks and tiles of different varieties and specifications can be produced, which has obvious economic and social benefits.