Processing technology of extruder

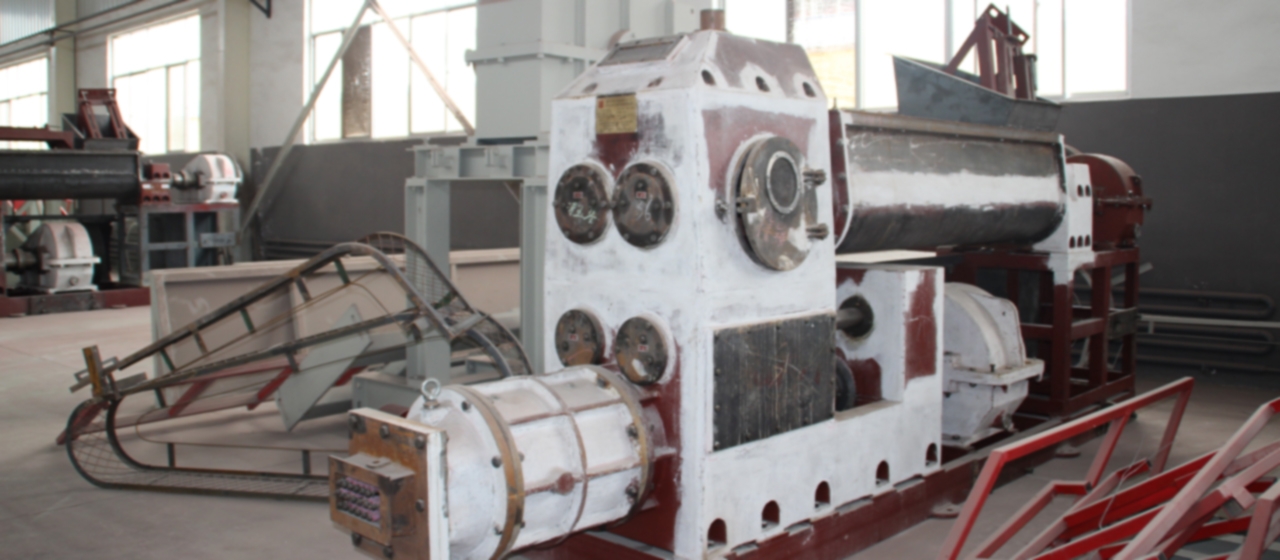

The vacuum extruder adopts single machine extrusion principle, single shaft, single mud cylinder and single screw coaxial sealing mechanism. The machine body is welded by steel plates. Reasonable structure design and high extrusion pressure. It is suitable for producing hollow bricks of various specifications from shale, high content fly ash, coal gangue, clay and other raw materials. The machine has strong practicability, small investment and quick effect. It is an ideal equipment for technical transformation of brick factory.

Improve the conveying balance of brick machine. For well formed block products, if the conveying plane of the blank feeder is uneven, it will also crack during the conveying of block products, especially for products mixed with fly ash. When the supporting plate is thin and variable, it is most likely to crack.

Therefore, we divide the chain conveyor and roller conveyor of the plate feeder into two parts for design and manufacture, and use adjustable bolts for connection, so as to ensure that the upper plane of the chain and the upper plane of the idler are on the same plane, ensure that the pallet can be smoothly transported from the chain to the idler, improve the qualification rate of the products and reduce the cracking of the products.