Product Introduction:

Rotary Logo Brick Machine:

1.logo brick machines press different bricks.Free gifts a set of logo custom molds。The logo can be as deep as 10mm.

2.We provide the design and construction of the entire brick production line. 24 -hour technical support and video guidance.

3.fully automatic hydraulic operations, and higher hardness quality of finished bricks.

Product Paramenters

|

Model

|

capacity (yuan/hour)

|

Size(M)

|

molding moisture

|

Speed (RPM)

|

Motor (kw)

|

The motor pulley(Starting)

|

Starting the system pressure (kg/cm3)

|

|

YH35-10

|

4000-6000

|

3.3 * 1.6 * 2.3

|

17% – 21%

|

4.706

|

37 + 3

|

150

|

3.5 to 7

|

|

typing depth to 10 mm, frequency converter, so the speed can be adjust according to the soil humidity and hardness, can be motor driven or diesel engine, the weight of 5.2 tons, a minute five laps, diameter of 1.1 meters, the mixing length 2.2 meters.

|

|||||||

|

Lubrication part: Spray the oil on the mold to keep the mold clean, even and controllable.Brick is arranged well. There is also an air press, which is used in the pneumatic clutch and oil spraying on the brick machine.

|

|||||||

Product Parts:

|

|

|

|

Auger |

Thrust bearing |

Reducer |

| Auger adopts high chromium raw materials,the auger front part can produce 25million bricks,the auger back part can produce 45 million bricks one time. | High load capacity to admit any pressure from soft to stiff extrusion condition. | Reducers with parallel shafts,case hardened and ground helical gears to ensure secure,progressive transmission and quiet operation and long durability. |

Extruder shaft |

Liner |

| Extruder shaft and gear adopts heat treatment.If with proper maintenance,we can give at least 4 years guarantee for gears and shaft. | 1.Hinged body.Easy opening for maintenance tasks and part replacement.

2.Highly wear resistant chrome alloy liners with a bolt-free system,preventing air leaks and making replacement operations easier. |

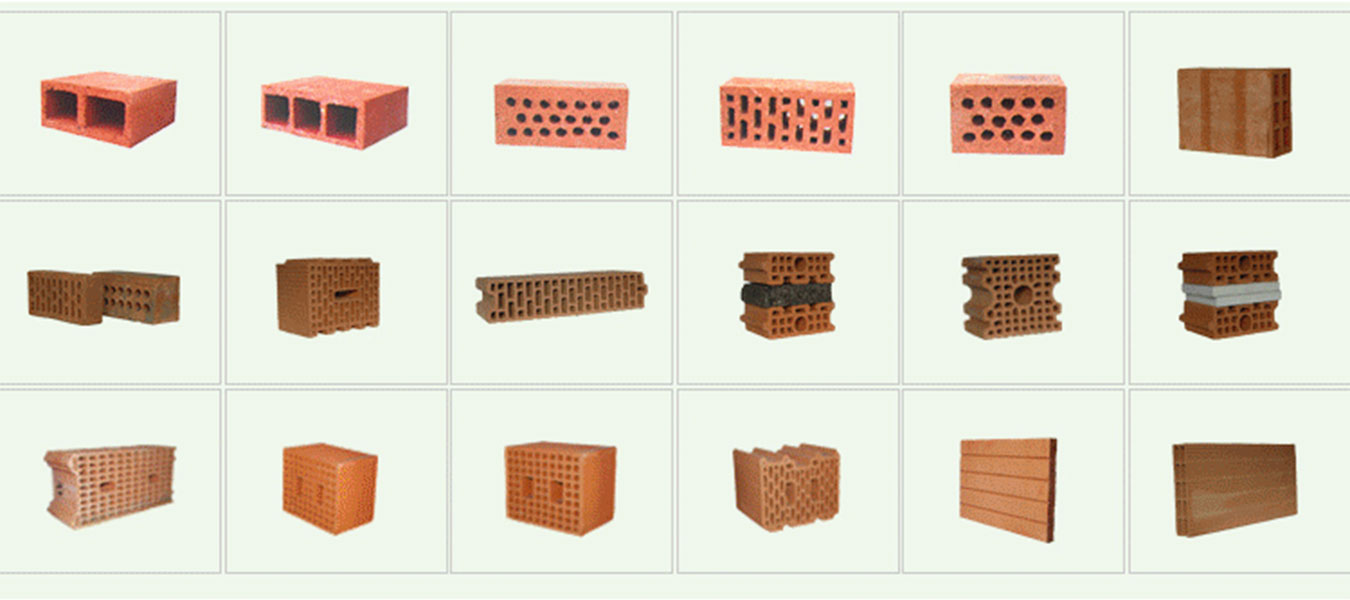

Making different bricks: