Product Introduction:

Hammer crusher can crush the material with a maximum particle size of 600-1800 mm to 0 or 8 mm or less,Hammer crusher is suitable for shale, coal gangue,chemicals, and other industrial sectors to crush medium hard materials .

The Hammer head body adopts medium-manganese nodular cast iron .Hardness value may reach HRC60~62°.

Advantages:

High structure,Low cost,delivering a high (2%-20%) moisture content of raw materials,the most widely used clay crusher machine.

Product Parts:

Alloy mixer blades |

Alloy hollow brick mould |

Alloy brick mould |

Auger |

Thrust bearing |

Reducer |

| Auger adopts high chromium raw materials,the auger front part can produce 25million bricks,the auger back part can produce 45 million bricks one time. | High load capacity to admit any pressure from soft to stiff extrusion condition. | Reducers with parallel shafts,case hardened and ground helical gears to ensure secure,progressive transmission and quiet operation and long durability. |

Extruder shaft |

Liner |

| Extruder shaft and gear adopts heat treatment.If with proper maintenance,we can give at least 4 years guarantee for gears and shaft. | 1.Hinged body.Easy opening for maintenance tasks and part replacement.

2.Highly wear resistant chrome alloy liners with a bolt-free system,preventing air leaks and making replacement operations easier. |

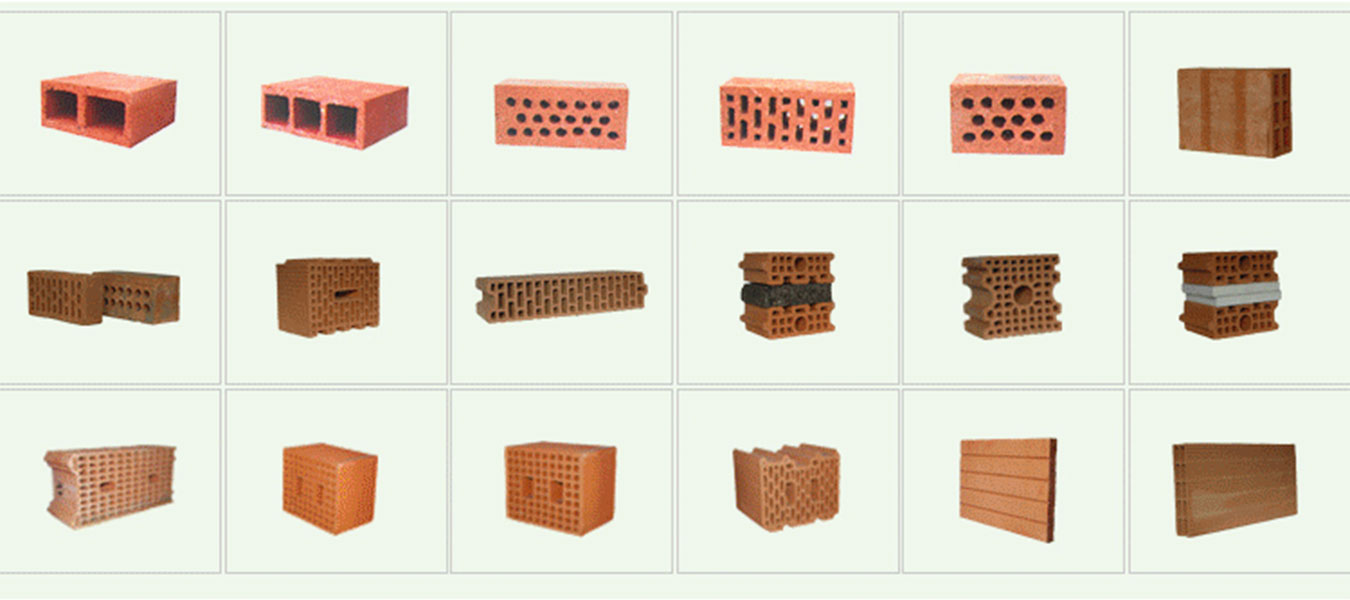

Making different bricks: